Udaka lwamatshe luyingxube yempushana yamatshe namanzi akhiqizwa ngesikhathi sokusika nokupholishwa kwemabula negwadle.Izindawo eziningi ezisenyakatho yezwe lethu ziyizisekelo ezibalulekile zokucubungula amatshe, futhi inani elikhulu lodaka lwamasaha likhiqizwa minyaka yonke, futhi ukupakishwa kwalo kuthatha. phezulu indawo enkulu yezinsiza zomhlaba.Impushana yamatshe inokwakheka okuhle futhi kunzima ukuyilahla. Kulula ukundiza esibhakabhakeni emoyeni onamandla, futhi ageleza emfuleni namanzi emvula ezinsukwini zemvula, okubangela ukungcoliswa okukhulu kwemvelo.

Amaminerali e-ganggue ayinhloko odaka lwamasaha ahlanganisa i-feldspar, i-quartz, i-calcite, i-dolomite, i-amphibole, njll. Amaminerali ensimbi ayinhloko nokungcola kuhlanganisa i-iron silicate njenge-mechanical iron, i-magnetite, i-iron oxide, i-pyrite, ne-biotite. Okwamanje, ukusetshenziswa okuphelele indlela yodaka lwamasaha iwukukhiqiza izitini ezinokhonkolo ezine-aerated nokwenza izinto zokusetshenziswa zobumba zobumba ngemva kokukhipha ukungcola. Eyangaphambili inamandla amakhulu okucutshungulwa kanti lena inezinzuzo eziphezulu zezomnotho.

Ucwaningo lokuhlomula

Kulesi sihloko, ucwaningo olunzulu lokuhlola ukusetshenziswa nokuzuza lwenzelwa ummeleli wabona udaka endaweni ye-Jining.Amaminerali abalulekile odakeni olusaha yi-feldspar, insimbi yomshini, insimbi kazibuthe, njll., nokungcola okuyingozi yi-limonite, biotite, i-muscovite, i-calcite, i-dolomite, i-hornblende, njll. Ubukhulu bezinto ezibonakalayo azilingani, izinhlayiya eziqinile zisuka ku-1-4mm nodaka oluthile -0.037mm. Phakathi kwazo, insimbi yomshini ekhiqizwa ngesikhathi sokucutshungulwa kanye nensimbi magnetic endaweni eluhlaza i-ore ingahlukaniswa ngozibuthe ibe yimikhiqizo ye-iron concentrate. Ngemva kokuhlukana okuqinile kazibuthe, ukungcola okunensimbi okufana ne-limonite, i-biotite, ne-amphibole kungasuswa. Imikhiqizo yokugxilisa amatshe, ingxenye ngayinye yemisila kazibuthe ingasetshenziswa njengezitini ezifakwe umoya noma izinto zikasimende, ukuze kufezwe inhloso yokusetshenziswa okuphelele.

1.Ukunqunywa kokugeleza kwenqubo

Ukuhlanganisa izakhiwo zesampula ye-sawdust ukuze kutholwe inqubo yokuzuza: insimbi eluhlaza ihlungwa ngemisebe engama-30-+30 anezikhala ezimahhadla-okusanhlamvu okugaywayo kube -30 anezikhala.

—--30 anezikhala ezixube isampula ukuhlukaniswa kwensimbi ngesigubhu sikazibuthe isihlukanisi + ipuleti flat + indandatho mpo + mpo mpo + vertical ring ukususwa kwensimbi kazibuthe-okugxilile ihlukaniswa 300 anezikhala medium-grain okusanhlamvu imikhiqizo feldspar concentrate kanye -300 anezikhala ezinhle zodaka—-Udaka olucolile lube selusetshenziselwa ukususa insimbi kabili ngodaka lukagesi ukuze kutholwe umkhiqizo ogxilile wezinga lempushana.

2.Ukuhlolwa kokuhlukaniswa kwe-ore eluhlaza

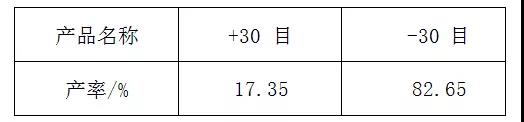

I-ore eluhlaza yahlungwa ngamameshe angama-30, futhi imiphumela yokuhlaziya ikhonjiswe kuThebula 1.

Ithebula 1. Umphumela Wokuhlolwa Kwenzuzo Nokuhlolwa

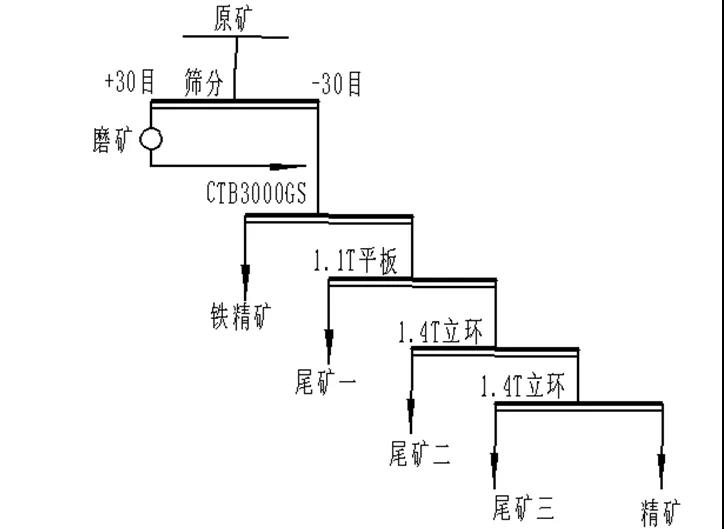

Gaya i-ore eqinile ngesivuno esingu-17.35% kuya ku-30 mesh, xuba nomkhiqizo ngaphansi kwesisefo, bese udlulela kunqubo evamile yokuhlukanisa kazibuthe yesihlukanisi sikazibuthe sesigubhu + ipuleti eliyisicaba + indandatho eqondile + indandatho eqondile. Ukugeleza kwenqubo kuboniswa kuMfanekiso 1, futhi imiphumela yokuhlolwa ikhonjiswe kuThebula 2.

Umfanekiso 1. Ukugeleza kwenqubo yokuhlolwa okujwayelekile kokuhlukanisa kazibuthe kwensimbi eluhlaza.

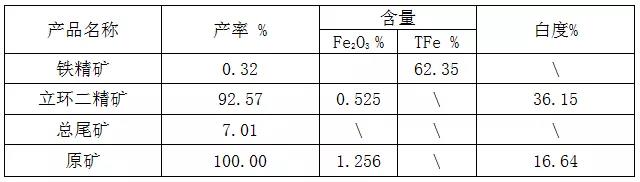

Ithebula 2. Imiphumela yokuhlolwa okujwayelekile kokuhlukanisa kazibuthe

I-ore eluhlaza ihlolwe + ukugaya i-ore + inqubo evamile yokuhlola ukususwa kwensimbi izikhathi ezintathu, futhi imikhiqizo yokugxilisa ingqondo emaphakathi nendawo ephansi ingatholakala ngesivuno esingu-92.57%, okuqukethwe kwe-Fe2O3 okungu-0.525% nomhlophe okungu-36.15%. Kufanele kucatshangelwe ukuhlanza i-iron oxide enezinhlamvu ezinhle kanye ne-iron silicate odakeni oluhle ngomshini ophakathi nendawo, umshini we-electromagnetic slurry osezingeni eliphezulu ngemuva kokuhlukaniswa.

3.Ukususwa kwe-ayina odaka oludaka olucolekile

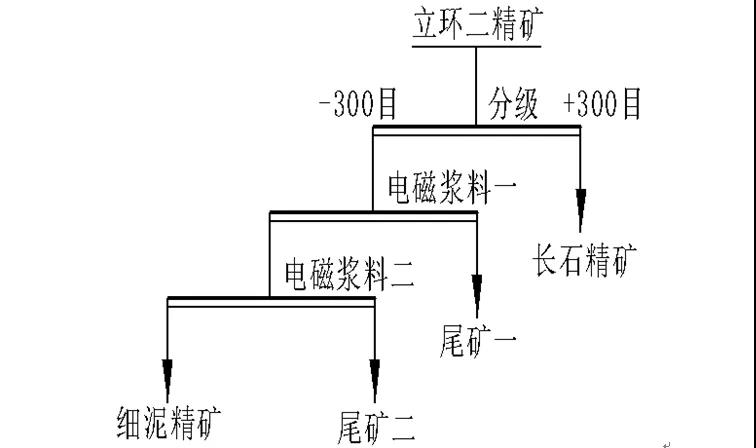

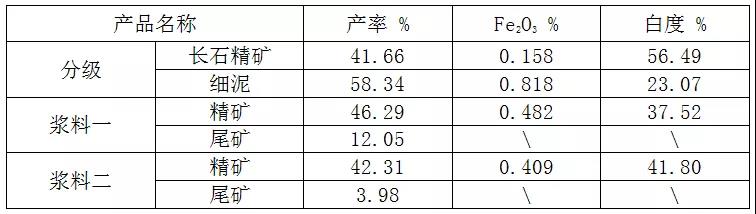

I-concentrate yesibili ye-Lihuan ikhishwa ku-sludge emihle engezansi -300 mesh ngokusebenzisa ukuchichima, futhi inqubo yokukhipha insimbi kabili ngomshini we-electromagnetic slurry isetshenziselwa ukuthola umkhiqizo omuhle we-powder. Ukugeleza kwenqubo kuboniswa kuMfanekiso 2, futhi imiphumela yokuhlolwa ikhonjiswe kuThebula lesi-3.

Umfanekiso 2. Ukugeleza kwenqubo yokuhlolwa kokukhipha insimbi yodaka olucolekile

Ithebula 3. Inkomba yokukhipha insimbi yodaka olucolekile

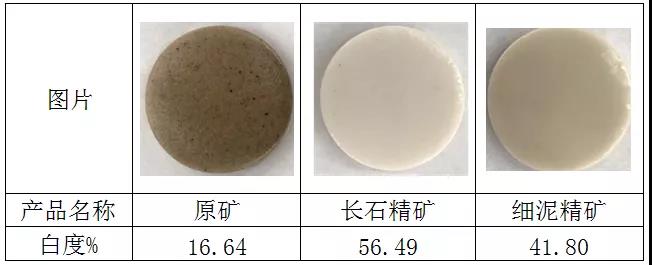

Ngemva kokulinganisa i-Lihuan concentrate, ubumhlophe be-+300 mesh medium-grain concentrate ye-feldspar bukhule busuka ku-36.15% baya ku-56.49%, futhi ubumhlophe bodaka oluhlehla lwaba ngu-23.07%. -I-300 mesh fine sludge ikhishwa ensimbi kabili nge-electromagnetic slurry, kanye nomkhiqizo we-ceramic-grade powder okhiqiza isivuno esingu-42.31% kanye nobumhlophe obungu-41.80% ungatholakala.

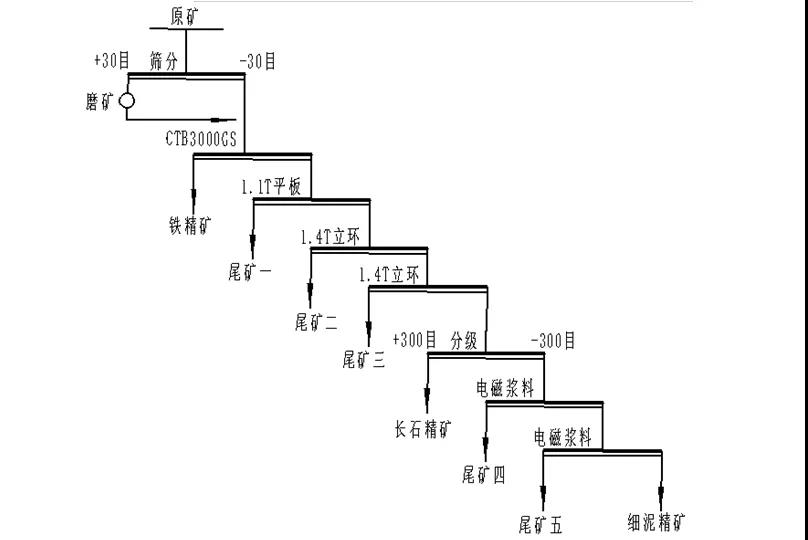

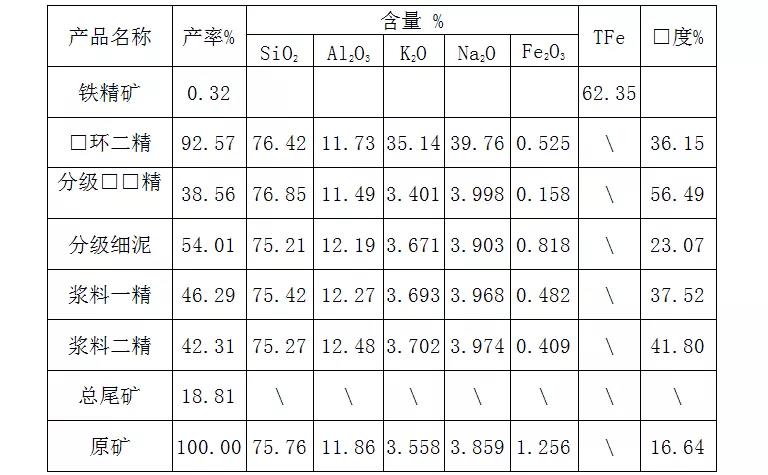

3.Ukuhlolwa kwenqubo yonke

Imibandela yokuhlola ephelele kanye nezinkomba zokwenza ukuhlolwa kwenqubo yonke.

Umfanekiso 3. Yonke inqubo yokuhlola udaka

Ithebula 4. Izinkomba zokuhlola zenqubo yonke

Okunamathiselwe: Izinga lokushisa lamabhisikidi 1200 ℃

Itshe lensimbi elisaha liyasefa + umhlabathi + ukuhlukaniswa kukazibuthe okubuthakathaka + ipuleti eliyisicaba + indandatho eqondile + indandatho eqondile + indandatho yokuhlukanisa i-electromagnetic slurry ukuze kutholwe insimbi enesivuno esingu-0.32% kanye nebanga le-TFe lama-62.35%. Ngesivuno esingu-38.56% kanye nobumhlophe be-54.69% yemikhiqizo yokugxila ye-ceramic grade ye-ceramic ye-feldspar kanye nesivuno se-42.31% yobumhlophe be-41.80% imikhiqizo ye-powder grade grade concentrate; isivuno esiphelele semisila kazibuthe ngu-18.81%, Ingasetshenziswa njengempahla eluhlaza yezitini ezifakwe umoya.

Le nqubo yobuchwepheshe ivumela ukusetshenziswa okuphelele kwezinsalela zodaka, futhi ingathola izinzuzo eziphakeme zezomnotho kanye nokubaluleka kokuvikelwa kwemvelo kwezenhlalo.

Isikhathi sokuthumela: Mar-04-2021