Imithombo yensimbi yezwe lethu inothile ngezinqolobane nezinhlobonhlobo, kodwa maningi ama-ore athambile, ama-ore acebile ambalwa, kanye nembudumbudu esakazeka kahle. Kunama-ore ambalwa angasetshenziswa ngokuqondile. Inani elikhulu lama-ores adinga ukucutshungulwa ngaphambi kokuba asetshenziswe.Sekuyisikhathi eside, kuye kwaba nzima nakakhulu ukuhlomula phakathi kwama-ores akhethiwe, isilinganiso se-beneficiation siye saba sikhulu futhi sikhulu, inqubo kanye nemishini iye yaba ngaphezulu futhi. okuyinkimbinkimbi kakhulu, ikakhulukazi izindleko zokugaya zibonise ukuthambekela okukhulayo.Okwamanje, izitshalo zokucubungula ngokuvamile zisebenzisa izinyathelo ezifana nokuchotshozwa okwengeziwe nokugaya kancane, nokukhethwa kwangaphambili nokulahlwa kwemfucuza ngaphambi kokugaya, okuthole imiphumela ephawulekayo.

Ngokuvamile, ukuphonsa okomile bngaphambili ukugaya kunenzuzo enkulu kule situati elandelayoOs:

(1) Ngeizindawolapho imithombo yamanzi iyivelakancane, amanzi okuthuthukiswa kwezimayini awanakuqinisekiswa, okwenza ukuba kube nokwenzeka kokuhlukaniswa kwezimbiwa ezimanzi kungabi phezulu. Ngakho-ke, kulezi zindawo, izindlela ezomile zokukhethwa kwangaphambili zizocatshangelwa kuqala.

(2) Kuyadingeka ukunciphisa umthamo we-tailings slurry futhi unciphise ukucindezela kwechibi le-tailings. Okubalulekile kuzonikezwa ukomisa ukukhetha kwangaphambilini nokulahlwa kukadoti.

(3) Ukuphonswa okomile kwensimbi eyizinhlayiya ezinkulu kungenzeka kakhulu kunokuhlukaniswa kwamanzi.

(4) Ukuphonsa okomile kuvame ukuhlukaniswa ngezigaba eziningana:

Ukuphonswa okomile kwemikhiqizo echotshoziwe ngamaqhafuqhafu enobukhulu bezinhlayiyana obungama-400~125 mm,Ukupholishwa okomile kwemikhiqizo echotshoziwe okuphakathi enobukhulu bezinhlayiyana obungu-100-50 mm,Ukuchotshozwa okuhle nokupholishwa okomile okunobukhulu bezinhlayiyana obungama-25.~5 mm, Kanye nokupholishwa okomile kwemikhiqizo echotshoziwe yizigayo ze-high-pressure roller, ezisetshenziswa kabanzi okwamanje, ukwakheka kwemishini ekhethiwe kuhlukile.

Imishini yokuhlukanisa eyomile yezinto ezinobukhulu bezinhlayiyana ezingama-20 mm noma ngaphezulu

Ngokupholishwa okomile kwe-ore enosayizi omkhulu wezinhlayiyana ongu-20 mm noma ngaphezulu, uchungechunge lwe-CTDG oluhlala unomphela oluyisihlukanisi senqwaba kazibuthe lusetshenziswa kakhulu.

Izihlukanisi ezihlala unomphela ezinozibuthe ezinobuningi obuqinile zisetshenziswa kakhulu ezimayini zensimbi nezinye izimboni ukuhlangabezana nezidingo zezimayini ezinkulu, eziphakathi nezincane. Zisetshenziselwa ukukhethwa kwangaphambili kwezinto ezinobukhulu bezinhlayiyana ezingeqile ku-500 mm ngemva kokuchotshozwa esitshalweni sokuhlukanisa kazibuthe. Ukubuyisela izinga le-geological of the waste rock, lingonga amandla futhi linciphise ukusetshenziswa, futhi andise amandla okucubungula embonini yokucubungula;Isetshenziswa esitobhini ukuze kubuyiselwe insimbi kamagnetite edwaleni lemfucumfucu ukuze kuthuthukiswe izinga lokusetshenziswa kwemithombo yensimbi; isetshenziselwa ukubuyisela insimbi yensimbi kusuka ku-steel slag; isetshenziselwa ukulahla udoti ukuhlunga izinsimbi eziwusizo.

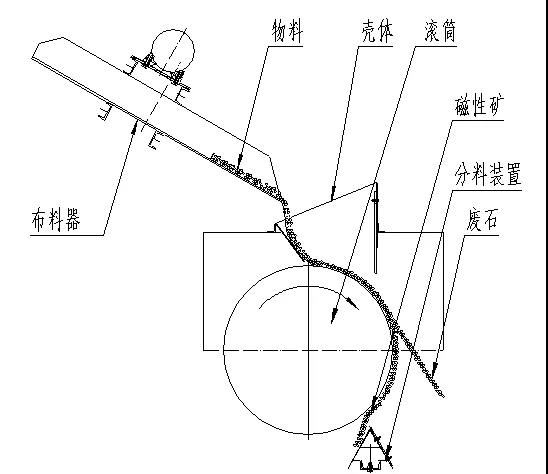

Isihlukanisi esinozibuthe esinozibuthe omile ngobuningi sisebenzisa amandla kazibuthe ngokuhlukanisa, Insimbi ifakwa ngokulinganayo ebhandeni bese iyiswa endaweni yokuhlungwa engxenyeni engenhla yesigubhu sikazibuthe ngesivinini esingaguquki.Ngaphansi kokusebenza kwamandla kazibuthe, amandla kazibuthe aqinile amaminerali adsorbed phezu kwebhande lezigubhu kazibuthe, agijimele engxenyeni engezansi yesigubhu futhi ahlukane nenkundla kazibuthe, futhi awele ethangini lokugxila ngamandla adonsela phansi. I-waste rock kanye ne-ore kazibuthe ebuthakathaka ayikwazi ukukhangwa amandla kazibuthe futhi igcine inertia yakho. Yaphonswa yayisicaba phambi kwe-partitioning partition yase iwela endaweni yokudoba.

Ngokombono wesakhiwo, isihlukanisi esihlala unomphela sikazibuthe senqwaba enozibuthe ikakhulukazi sihlanganisa idrayivu ye-drive, ukuhlanganisa iphinikhodi okunwebekayo, i-drive reducer, ukuhlanganisa ama-slide esiphambano, ukuhlanganisa izigubhu kazibuthe kanye nesinciphisi sokulungisa kazibuthe.

Amaphuzu obuchwepheshe besakhiwo

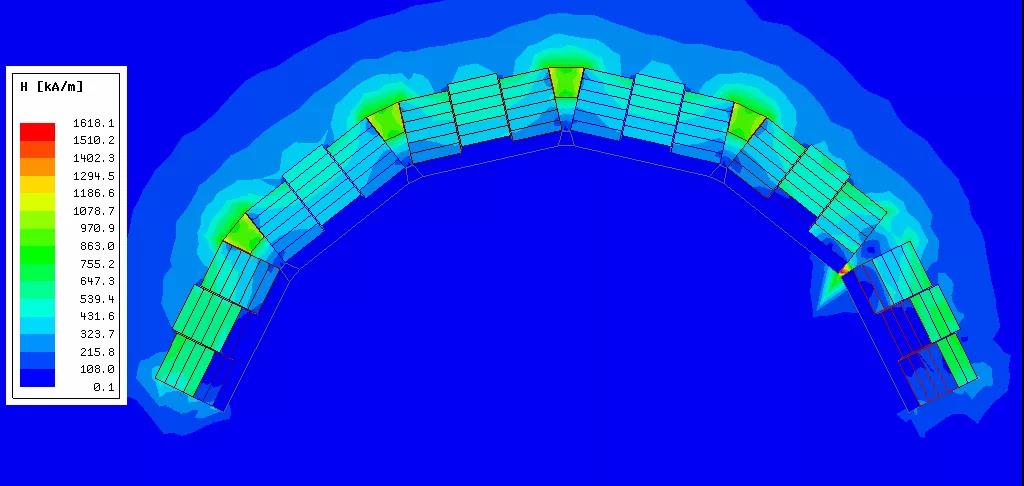

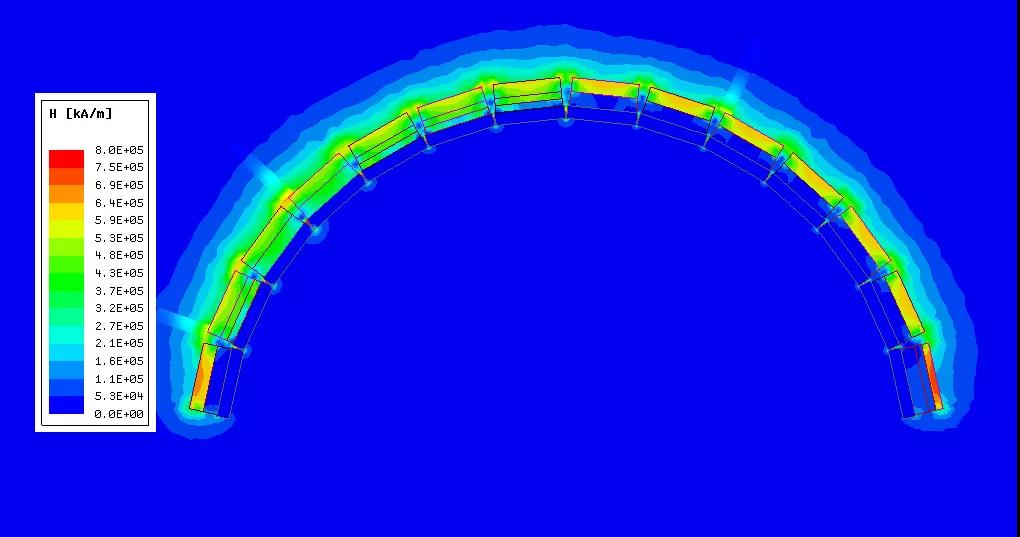

(1) Ukuze kuphonswe okomile kwemikhiqizo echotshoziwe ngamaqhafuqhafu enobukhulu bezinhlayiyana obungama-400-125 mm. Ngenxa yobukhulu be-ore enkulu, ibhande lidlulisela inani elikhulu ngemva kokuchotshozwa okuqinile, futhi ingxenye engaphezulu yesithumeli sebhande ingena endaweni yokuhlunga isigubhu. isigubhu kazibuthe kulesi sigaba sidinga ukujula kokungena kazibuthe okukhulu, ukuze kubanjwe izinhlayiya ezinkulu ze-ore.Amaphuzu obuchwepheshe abalulekile esakhiwo somkhiqizo kulesi sigaba:①Uma umkhulu ububanzi berola, kungcono, ngokuvamile kufika ku-1 400 mm noma 1 500 mm.②Ububanzi bebhande bukhulu ngangokunokwenzeka. Ubukhulu bokuklama ububanzi bebhande elikhethiwe okwamanje buyi-3 000 mm; ibhande lide ngangokunokwenzeka engxenyeni eqondile eduze kwenhloko yesigubhu, ukuze ungqimba lwempahla olungena endaweni yokuhlunga luncishiswe.③Ukujula okukhulu kokazibuthe kokungena. Thatha ukuhlungwa kwezinhlayiya ze-ore ezinobukhulu bezinhlayiyana ezingama-300-400 mm njengesibonelo. Ngokuvamile, amandla kazibuthe ebangeni lika-150-200 mm ukusuka endaweni yesigubhu ukusuka endaweni yokumunca isigubhu kuya endaweni yesigubhu kungaphezu kuka-64kA/m, njengoba kukhonjisiwe kuMfanekiso 1. 1.④Igebe phakathi kwepuleti lokuhlukanisa kanye isigubhu sikhulu kuno-400 mm futhi siyalungiseka. ⑤Isivinini sokusebenza sesigubhu siyalungiseka, futhi ukulungiswa kwe-engeli yokwehla kazibuthe kanye nokulungiswa kwedivayisi yokusabalalisa kwenza inkomba yokuhlunga ibe ngokufanele.

Umfanekiso 1 Imephu yefu yenkundla kazibuthe

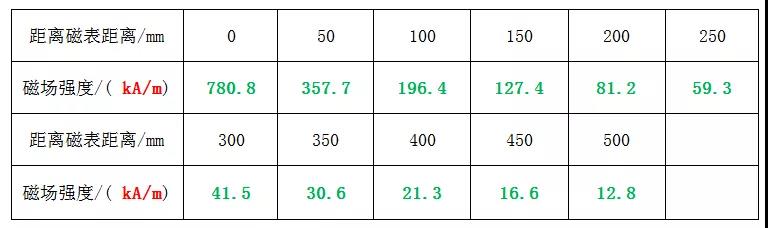

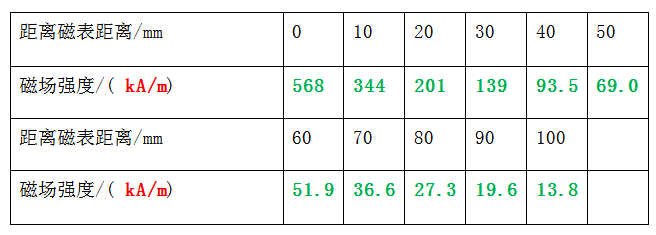

Ithebula 1 Ukuqina kwenkundla kazibuthe ebangeni elithile ukusuka kuthebula likazibuthe kA/m

Kuyabonakala kuThebula 1 ukuthi amandla kazibuthe ebangeni elingama-200 mm ukusuka ebusweni besistimu kazibuthe angama-81.2 kA/m, futhi amandla kazibuthe ebangeni elingama-400 mm ukusuka ebusweni besistimu kazibuthe. 21.3 kA/m.

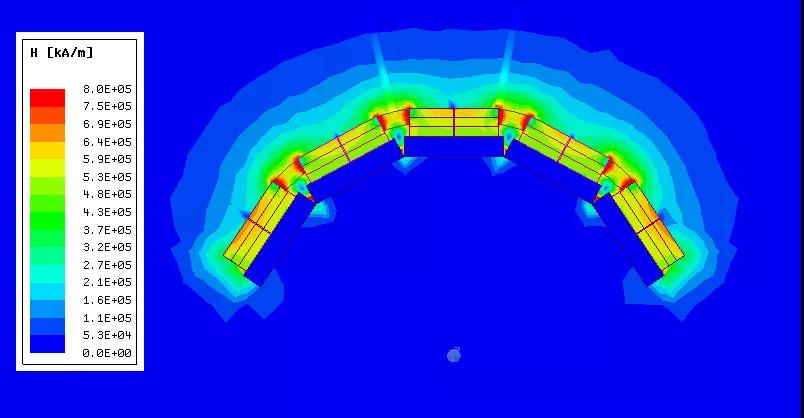

(2) Ukuze kupholishwe okomile kwemikhiqizo echotshoziwe ephakathi nendawo enobukhulu bezinhlayiyana obungu-100-50 mm, ngenxa yobukhulu bezinhlayiyana ezincane kanye nongqimba lwempahla oluncane, imingcele yokuklama kanye nokukhetha okomile okuchotshozwayo kungalungiswa ngokufanele:①Ububanzi besigubhu kuvame ukuba yi-1 000, 1 200, 1 400 mm.②Ububanzi bebhande obujwayelekile buyi-1 400, 1 600, 1 800, 2 000 mm; ibhande lide ngangokunokwenzeka esigabeni esiqondile eduze kwekhanda lesigubhu, ukuze ungqimba lwempahla olungena endaweni yokuhlunga luncishiswe.③Ukujula okukhudlwana kokungena kazibuthe, ukuthatha ukuhlunga kwezinhlayiya zensimbi ezinobukhulu bezinhlayiyana eziyi-100 mm njengesibonelo, ngokuvamile amandla kazibuthe ebangeni lika-100-50 mm ukusuka endaweni yesigubhu ukusuka endaweni yokudonsa imigqomo ukuya endaweni yesigubhu ngaphezu kuka-64kA/m, njengoba kukhonjisiwe kuMfanekiso 2 kanye neThebula 2.④Igebe phakathi kwepuleti lokuhlukanisa nesigubhu likhulu kuno-100 mm futhi liyalungiseka.⑤Isivinini sokusebenza sesigubhu siyalungiseka, futhi ukulungiswa kwe-engeli yokwehla kazibuthe kanye nokulungiswa kwedivayisi yokusabalalisa kwenza inkomba yokuhlunga ibe ngokufanele.

Umfanekiso 2 Imephu yefu yenkundla kazibuthe

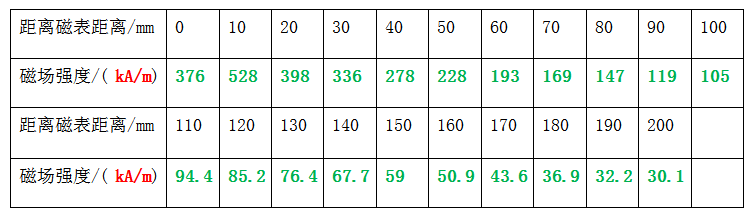

Ithebula 2 Ukuqina kwenkundla kazibuthe ebangeni elithile ukusuka kuthebula likazibuthe kA/m

Kungabonakala kuThebula 2 ukuthi amandla kazibuthe ebangeni elingu-100 mm ukusuka ebusweni besistimu kazibuthe ngu-105 kA/m, kanye namandla kazibuthe ebangeni elingama-200 mm ukusuka ebusweni besistimu kazibuthe. 30.1 kA/m.

(3) Ngokupholishwa okomile kwemikhiqizo ehlukaniswe kahle enobukhulu bezinhlayiyana obungu-25-5 mm, ububanzi besigubhu esincane kanye nokujula kokungena kazibuthe okuncane kungakhethwa ekwakhiweni nasekukhethweni, okungeke kuxoxwe ngakho lapha.

Imishini yokomisa yezinto ezinobukhulu bezinhlayiyana ezingaphansi kuka-20 mm.

- Uchungechunge lwe-MCTF oludonsa isihlukanisi esinozibuthe esomile

Uchungechunge lwe-MCTF oludonsa isihlukanisi esinozibuthe esomile siwumshini ophakathi nendawo wamandla kazibuthe wokuhlukanisa. Ilungele izinsimbi ezithambile ezifana netshe le-sandstone, i-sand ore, isihlabathi somfula, isihlabathi solwandle, njll.~0 mm. Ukugxiliswa kwamaminerali kazibuthe kanye nokukhethwa kwangaphambili okomile kwemikhiqizo yamagnetite echotshoziwe.

1.2 Umgomo wokusebenza

Umgomo wokusebenza wochungechunge lwe-MCTF oludonsa isihlukanisi esinozibuthe esomile uboniswa kuMfanekiso 3.

Umfanekiso 3 Umdwebo wohlelo lwesimiso sokusebenza sohlobo lwe-MCTF oludonsa isihlukanisi sikazibuthe esomile

Kusetshenziswa isimiso sokuthi izinto zikazibuthe zingakhangwa ngozibuthe baphakade, uhlelo lukazibuthe oluyisiyingi esinendawo enkulu kazibuthe lusethwa ngaphakathi kwesigubhu okugeleza ngaso okokubalulekile. amandla kazibuthe aqinile futhi akhangisiwe ebusweni besistimu kazibuthe eyisiyingi.Lapho izinhlayiya zamaminerali kazibuthe zilethwa endaweni ephansi engeyona-magnetic ngesigubhu esijikelezayo, ziwela endaweni yokugxilisa ingqondo futhi zikhishwe ngaphansi kwesenzo samandla adonsela phansi. I-non-magnetic ore noma insimbi enezinga lensimbi ephansi ingageleza ngokukhululekile endaweni kazibuthe iye endaweni yokukhipha umsila ngaphansi kwesenzo samandla adonsela phansi namandla amaphakathi.

Ngokombono wesakhiwo, isihlukanisi sikazibuthe esomile sohlobo lwe-MCTF sihlanganisa ikakhulukazi idivayisi yokulungisa isistimu kazibuthe, ukuhlanganiswa kwemigqomo, igobolondo eliphezulu, isembozo sothuli, uhlaka, idivayisi yokudlulisela, nedivayisi yokusabalalisa.

Amaphuzu obuchwepheshe besakhiwo

Amaphuzu obuchwepheshe abalulekile esakhiwo ahlanganisa: ①Amadayamitha erola avame ukusetshenziswa angu-800, 1,000, kanye no-1 200 mm; idizayini ilandela isimiso sokuthi usayizi wezinhlayiyana ocolekile uhambisana nobubanzi obuncane, futhi uma ungqimba usayizi wezinhlayiyana uhambisana nobukhulu bobubanzi besigubhu.②Ubude besigubhu ngokuvamile bulawulwa ngaphakathi kuka-3,000 mm. Uma isigubhu siside kakhulu, indwangu ngeke ifane ohlangothini lobude, okuzophazamisa umphumela wokuhlunga.③Njengoba usayizi wezinhlayiyana zezinto ezibonakalayo uba mncane, ukujula kozibuthe kokungena kwesigubhu kuba kuncane; inani lezigxobo kazibuthe liyakhula, elihambisana nokuguqulwa okuningi kwezinto ezibonakalayo futhi liqaphela ukuhlukaniswa kwemisila ecwengekile yezinto ezibonakalayo; uma ugqinsi longqimba olubalulekile lingu-30 mm, ibanga ukusuka endaweni yesigubhu lingu-30 Amandla kazibuthe ku-mm ngu-64kA/m, bheka uMdwebo 4 kanye neThebula 3.④Igebe phakathi kwepuleti elihlukanisayo nesigubhu likhulu kuno-20 mm futhi iyalungiseka. ⑤Ukuze uqinisekise ukusatshalaliswa okufanayo kubude besigubhu, okokusebenza kufanele kuhlonyiswe ngezinto ezisizayo ezifana ne-chute, isiphakeli esidlidlizayo, isisabalalisi esivunguzayo noma isisabalalisi senkanyezi.⑥Ngokwenkomba yokuhlunga okuzinzile, ingafakwa idivayisi yokufaka amamitha ukuze ibone. ukudla okulinganiselwe. ⑦ Isivinini sokusebenza sesigubhu siyalungiseka, futhi ukulungiswa kwe-engeli yokwehla kazibuthe kanye nokulungiswa kwedivayisi yokusabalalisa impahla kwenza inkomba yokuhlunga ibe ngokufanele. Indawo esetshenziswayo ye-MCTF edonsa isihlukanisi esinozibuthe esomile esinesifunzi esidlidlizayo iboniswa kuMfanekiso 5.

Umfanekiso 4 Imephu yefu yenkundla kazibuthe

Ithebula 3 Ukuqina kwenkundla kazibuthe ebangeni elithile ukusuka kuthebula likazibuthe kA/m

Kuyabonakala kuThebula 3 ukuthi amandla kazibuthe ebangeni elingama-30 mm ukusuka ebusweni besistimu kazibuthe ngu-139kA/m, futhi amandla kazibuthe ebangeni elingu-100 mm ukusuka ebusweni besistimu kazibuthe ngu-13.8 kA/m.

Umfanekiso 5 Indawo yohlelo lokusebenza ye-MCTF edonsa isihlukanisi esinozibuthe esomile ngesiphakeli esidlidlizayo

2.MCTF uchungechunge double isigubhu pulsating esomile magnetic isihlukanisi

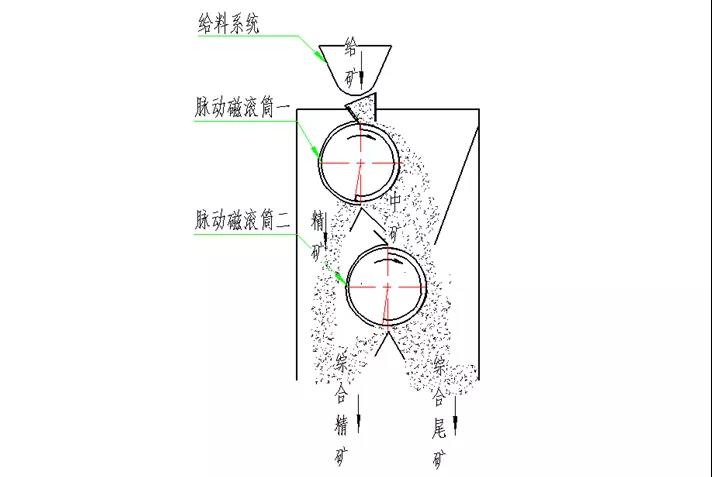

2.1 Umgomo wokusebenza wokushanela kanzima

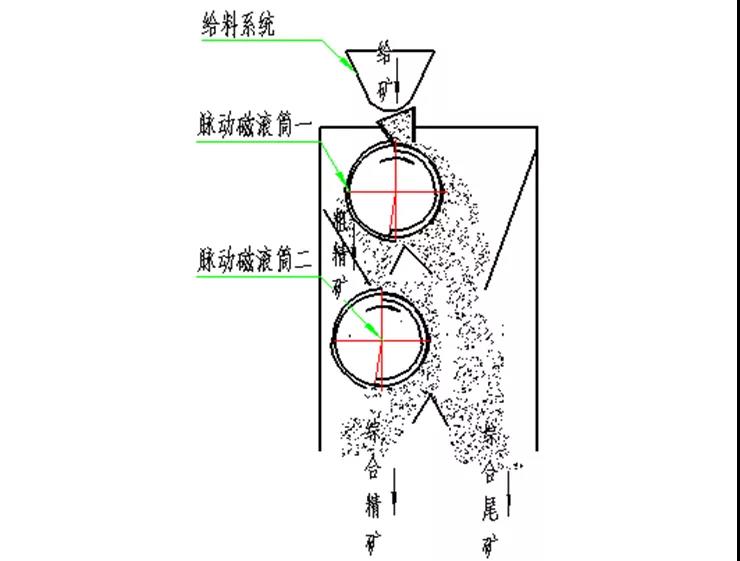

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela. Ngemva kokuba insimbi ihlungwa ngesigubhu sokuqala, ingxenye ye-concentrate iqala ikhishwe. Imisila yesigubhu sokuqala ingena esigubhuni sesibili sokushanela, bese kuthi ukugxilisa okushanelayo kanye nokugxilisa ingqondo kuqala kuxutshwe ukuze kube ukugxilisa ingqondo kokugcina. , Imisila ehlutshiwe iyimisila yokugcina. Umgomo wokusebenza wokushanela okukodwa uboniswa kuMfanekiso 6.

2.2 Umgomo wokusebenza wenhlawulo eyodwa eyodwa

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela. Ngemva kokuba insimbi isihlungiwe ngesigubhu sokuqala, ingxenye yezinsalela iqala ilahlwa kude. I-concentrate yesigubhu sokuqala ingena esigubhuni sesibili ukuze sikhethwe, bese kuthi i-concentrate yesibili yokuhlunga isigubhu yi-concentrate yokugcina. Izinsika zokugqoka zesibili zihlanganiswa zibe yizinsalela zokugcina. Umgomo wokusebenza wenhlawulo eyodwa nenhlawulo eyodwa ukhonjiswe kuMfanekiso 7.

Umdwebo 7 Umdwebo womgomo wokusebenza wokungalungi nokuhle

Amaphuzu obuchwepheshe besakhiwo

Amaphuzu obuchwepheshe ochungechunge lwe-2MCTF lwesigubhu esiphindwe kabili esidonsa isihlukanisi sikazibuthe esomile:①Umgomo oyisisekelo wokuklama uyafana nochungechunge lwe-MCTF oludonsa isihlukanisi esinozibuthe esomile. ②Amandla kazibuthe weshubhu lesibili makhulu kunalawo eshubhu lokuqala lapho elokuqala limahhadla nokushanela kokuqala; amandla kazibuthe eshubhu lesibili liphansi kuneshubhu lokuqala lapho elokuqala limahhadla futhi elinye licolekile. Indawo yohlelo lokusebenza ye-2MCTF yesigubhu esiphindwe kabili esidonsa isihlukanisi esinozibuthe esomile esifakwe idivayisi yokudla okumise okwenkanyezi kanye nedivayisi yokulinganisa ezenzakalelayo iboniswa kuMfanekiso 8.

Umfanekiso 8 Indawo yohlelo lokusebenza ye-2MCTF yesigubhu esiphindwe kabili esidonsa isihlukanisi esinozibuthe esomile esifakwe idivayisi yokuphakela emise okwenkanyezi kanye nedivayisi yokulinganisa ezenzakalelayo.

3.3MCTF uchungechunge lwezigubhu ezintathu eziphephula isihlukanisi esinozibuthe esomile

3.1 Umgomo wokusebenza wokushanela okukodwa okuqinile nokubili

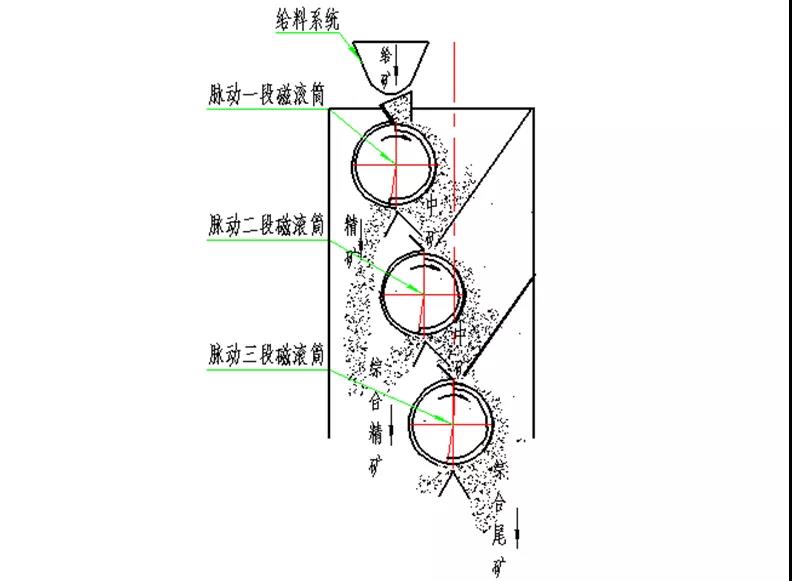

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela, insimbi ihlungwa ngesigubhu sokuqala, futhi ingxenye ye-concentrate iqala ikhishwe. Izisila zesigubhu sokuqala zingena kwesesibili sishanela isigubhu, okwesibili isigubhu singena kwesesithathu sishanela, bese kuthi okwesithathu sishanele isigubhu Ukuze kube nomsila wokugcina, ukugxilisana komgqomo wokuqala, wesibili, nowesithathu kuhlanganiswe kugxile ekugcineni. Umgomo wokusebenza wokushanela okukodwa okuqinile nokubili uboniswa kuMfanekiso 9.

Umfanekiso 9 Umdwebo owuhlelo wesimiso sokusebenza sokushanela okukodwa okumaholo nokubili

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela. Ngemva kokuba insimbi isihlungiwe ngesigubhu sokuqala, okugxilile kungena esigubhuni sesibili ukuze kuqhubeke ukuhlukaniswa, okugxilile kwesigubhu sesibili kungena ekuhlungeni isigubhu sesithathu, bese kuthi ukugxilisa kwesigubhu sesithathu kube ukugxila kokugcina. Imisila yesigubhu sesibili nesesithathu ihlanganiswa ibe isisila sokugcina. Umgomo wokusebenza wenhlawulo eyodwa elukhuni nezimbili uboniswa kuMfanekiso 10.

Umfanekiso 10 Umdwebo owuhlelo wesimiso sokusebenza senhlawulo eyodwa eyodwa kanye nezimbili

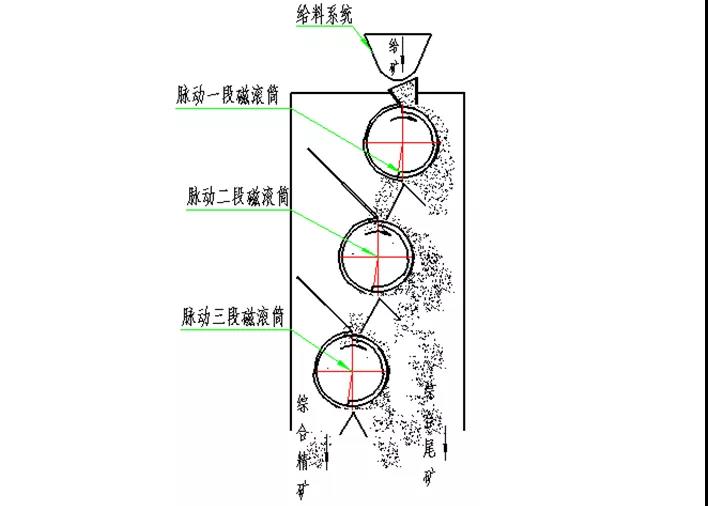

Amaphuzu obuchwepheshe besakhiwo

Amaphuzu obuchwepheshe ochungechunge lwe-3MCTF lwamarola amathathu aphephula isihlukanisi esinozibuthe esomile: ①Umgomo oyisisekelo wokuklama uyafana nochungechunge lwe-MCTF oludonsa isihlukanisi esinozibuthe esomile. ②Amandla kazibuthe weshubhu lesibili kanye neshubhu lesithathu ayanda ngokulandelana kokushanelwa okukodwa nokubili; amandla kazibuthe weshubhu lesibili kanye neshubhu lesithathu liyancipha ngokulandelana okukodwa okumaholo nokubili. Indawo esetshenziswayo yochungechunge lwe-3MCTF yesihlukanisi esinezigubhu ezintathu esidonsayo esomile siboniswa kuMfanekiso 11.

Umfanekiso 11 Indawo yohlelo lokusebenza ye-3MCTF enezigubhu ezintathu eziphephula isihlukanisi esinozibuthe esomile

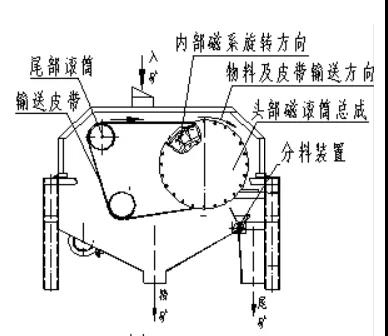

4. CTGY uchungechunge unomphela kazibuthe ezungezayo field magnetic isihlukanisi kazibuthe esomile

Umgomo wokusebenza wochungechunge lwe-CTGY umazibuthe unomphela ozungeza insimu kazibuthe isihlukanisi esisomile siboniswa kuMfanekiso 12.

Umfanekiso 12 Umgomo wokusebenza wochungechunge lwe-CTGY unomphela isihlukanisi kazibuthe esizungezayo esisomile.

CTGY uchungechunge unomphela uzibuthe ojikelezayo kazibuthe insimu pre-isikhethi [3] yamukela esiyinhlanganisela uhlelo kazibuthe, ngokusebenzisa amasethi amabili mechanical transmission mechanism, ibona ukuzungeza okuhlanekayo kwesistimu kazibuthe nesigubhu, ikhiqiza ushintsho ngokushesha polarity, ukuze impahla kazibuthe kungaba zihlukaniswe ibanga elide. I-medium ihlukaniswe ngokuphelele nezinto ezingezona uzibuthe nezibuthaka kazibuthe.

Impahla iwela ebhandeni lokudlulisa ngokusebenzisa imbobo yokudla ngenhla kwedivayisi yokudla, futhi ibhande lokudlulisa lihamba ngaphansi kwesenzo semoto ehlukanisayo, futhi inkambu kazibuthe ezungezayo izungeza kwelinye icala ngaphansi kwesenzo semoto (ngokuhlobene nebhande. ).Ngemva kokuthi okubalulekile kulethwe endaweni kazibuthe ngebhande lokudlulisa, izinto zikazibuthe zikhangiswa ngokuqinile ebhandeni futhi zibe ngaphansi kwesenzo esinamandla sikazibuthe, okuholela ekuphendukeni nasekugxumeni, "nokumpintsha" into engeyona i-magnetic ungqimba olungaphezulu lwento engaphansi kwesenzo samandla adonsela phansi namandla e-centrifugal. , Faka ngokushesha ibhokisi elingelona uzibuthe. Into kazibuthe ikhangiswe ebhandeni futhi iyaqhubeka nokusebenza ngaphansi kwesigubhu. Uma ishiya inkambu kazibuthe, ingena ebhokisini kazibuthe ngaphansi kwesenzo samandla adonsela phansi namandla aphakathi nendawo ukuze ibone ukuhlukaniswa okusebenzayo kwento kazibuthe nento engeyona i-magnetic.

Amaphuzu obuchwepheshe besakhiwo

Isakhiwo esiyisisekelo sochungechunge lwe-CTGY oluhlala unomphela oluzungezayo lukazibuthe isihlukanisi sikazibuthe esomile sihlanganisa uhlaka, ibhokisi lokuphakelayo, isigubhu, ibhokisi lensalela, ibhokisi lokugxilisa ingqondo, isistimu yokudlulisela kazibuthe, uhlelo lokudlulisela izigubhu, njll.

Amaphuzu wobuchwepheshe ochungechunge lwe-CTGY unomphela ojikelezayo kazibuthe isihlukanisi kazibuthe esomile:①Idizayini yesistimu kazibuthe isebenzisa uhlelo oluzungezayo olugxilile, i-engeli yokugoqa kazibuthe ingu-360°, isiqondiso esiyindilinga sihlelwa ngokushintshana ngokuvumelana ne-NSN polarity, kanye nobuchwepheshe bokugxila obuyingqayizivele iyasetshenziswa. Amaqembu e-NdFeB wedge magnetic block anezelwa phakathi kwamaqembu kazibuthe ukwenza isigubhu Amandla akhuphuka izikhathi ezingaphezu kuka-1.5, futhi inani lezigxobo kazibuthe liphindwe kabili ngesikhathi esifanayo, okwandisa inani lokuwa ngesikhathi senqubo yokuhlunga impahla, futhi ingalahla ngokuphumelelayo izinto ezinozibuthe ezibuthakathaka kanye nama-ganges axubile kumaminerali.Ukusebenza okuphezulu, ukuphoqelela okuphezulu, izinga lokushisa eliphezulu kanye nokumelana nokushisa okuphezulu okungavamile komhlaba i-neodymium iron boron isetshenziswa njengomthombo kazibuthe, kanye namapuleti we-pole magnetic are eyenziwe nge-high-permeability material DT3 kagesi ehlanzekile yensimbi, ethuthukisa kakhulu ukungena. I-core shaft inciphisa ukulahleka kwendawo kazibuthe, futhi amandla kazibuthe endaweni yesilinda kazibuthe athuthukiswa ngempumelelo, okuthuthukisa izinga lokutholwa kwezinto ezisetshenziswayo ze-ferromagnetic.②Isistimu kazibuthe yesigubhu iguqulwa imvamisa futhi ilawulwa isivinini ngokuhlukana. Amamotho amabili agiyelwe akhethiwe ukuze alawule isivinini sesigubhu kanye nokujikeleza kwesistimu kazibuthe ngokulandelana, futhi amamotho amabili agiyelwe alawulwa ngokulandelana ngama-inverter amabili. Ijubane lemoto lingashintshwa ngokulungisa imvamisa yemoto ngokuthanda kwakho , Ngokushintsha isivinini sokuzungeza sesigubhu kanye nesivinini sokuzungezisa sohlelo lukazibuthe, inani lokuwa kwezinhlayiya zamaminerali liyalawulwa.③Irola kazibuthe elihlala njalo umgqomo wenziwe ngengilazi yepulasitiki eqinisiwe ye-fiber eyenziwe nge-epoxy resin, egwema ukushisa kwe-roller futhi ikhulise amandla emoto ngenxa yomphumela we-eddy current.

5. Uchungechunge lwe-CXFG Lumisiwe Isihlukanisi Samagnetic

5.1 Isakhiwo esiyinhloko kanye nomgomo wokusebenza

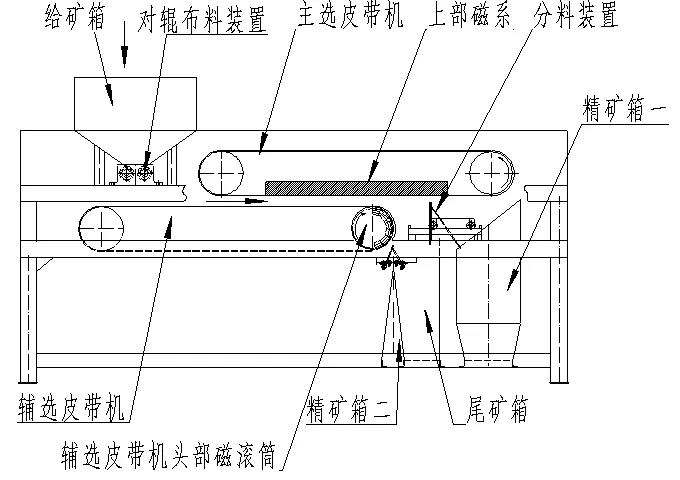

Isihlukanisi kazibuthe esiwuchungechunge lwe-CXFG ikakhulukazi sakhiwe ibhokisi lokuphakelayo, idivaysi yokusabalalisa i-counter-roller, i-conveyor yebhande eliyinhloko, i-auxiliary belt conveyor, isistimu kazibuthe, idivayisi yokusabalalisa, idivayisi yokumisa, ibhokisi lokugxila, ibhokisi le-tailings. , uhlaka kanye nokwakheka kwesistimu yokudlulisela.

Umgomo wokuhlunga wochungechunge lwe-CXFG lwesihlukanisi sokumiswa kazibuthe ukusebenzisa indlela yerola ukuze uphakele ngokulinganayo into engaphezulu kwebhande lokudlulisela lesixhumi esisizayo sebhande. Isistimu kazibuthe ku-conveyor yebhande elikhulu itholakala engxenyeni engenhla yezinto ukuze ihlukanise amaminerali aqinile kazibuthe. Iyathathwa bese ithunyelwa ebhokisini lokugxilisa ingqondo. Lapho izinto zikazibuthe ezibuthaka zidlula ekhanda le-axiliary belt conveyor, zimuncwa phezu kwesigubhu isimiso sikazibuthe esisegqomeni, bese ziwela ebhokisini lokugxilisa ingqondo ngemva kokuhlukaniswa nozibuthe njengoba isigubhu sizungeza. Amaminerali angewona azibuthe aphonswa ebhokisini lemisila ngaphansi kwesenzo samandla angenawo amandla okunyakaza namandla adonsela phansi, ukuze kufezwe injongo yokuhlunga. Umgomo wokusebenza we-CXFG uchungechunge lokumisa isihlukanisi kazibuthe uboniswa kuMfanekiso 13.

Umfanekiso 13 Umgomo wokusebenza we-CXFG uchungechunge lokumisa isihlukanisi kazibuthe

Amaphuzu obuchwepheshe besakhiwo

Amaphoyinti wobuchwepheshe we-CXFG yochungechunge lokumiswa kwesihlukanisi kazibuthe:①Ukusebenzisa indwangu yohlobo lwe-counter-roller akukwazi kuphela ukuqinisekisa ukufana komthamo wokucubungula kanye nesendlalelo sezinto ezibonakalayo, kodwa futhi kunganqanda kuphinde kusize ukuchotshozwa kwensimbi enkulu yokusanhlamvu. Kukhona igebe elithile phakathi kwamapheya amabili ama-roller. Ipheya lamagiya ahlanganayo ashayelwa ukuze azungezise ngokuhambisanayo nangokuhlehla ngenjini yokunciphisa imvamisa. Umsebenzisi angakwazi ukulungisa isivinini samarola ngokuya ngokuphumayo ukuze alungise inani lensimbi.②Ibhande elihlukanisayo eliyinhloko lamukela uhlelo oluvulekile lukazibuthe olunepulani, elinezigxobo kazibuthe eziningi ezihlelwa ngokushintshana. I-planar magnetic system inendawo yokuhlukanisa isikhathi eside kanye nesikhathi eside sokudonsa, okudala amathuba amaningi okukhangisa kwe-ore kazibuthe. Futhi ngenxa yokuthi isimiso sikazibuthe siyingxenye engenhla yensimbi, insimbi kazibuthe Endaweni yokuhlunga, isesimweni esimisiwe futhi esixegayo, i-monomer i-adsorbed, ayikho into efakiwe, kanye nokusebenza kahle kokuthuthukisa izinga ephakeme kakhulu kunaleyo yesistimu kazibuthe egobile.Amaminerali kazibuthe ahamba eduze kwezigxobo kazibuthe futhi adlule ohlelweni lukazibuthe lwendiza. Amaminerali kazibuthe aphendulwa ngokuzenzakalelayo izikhathi eziningi. Imvamisa yokuphenduka inkulu futhi isikhathi side, okuzuzisa ukuthuthukisa izinga lamaminerali kazibuthe.Kuhlelo lukazibuthe olucwathile, umklamo unomehluko kazibuthe ohlakaniphile nonengqondo, futhi amaminerali ahlala engaphansi kwesenzo se-multi- izigxobo ze-polar magnetic, ezihlukanisa ngempumelelo i-ganggue kanye namaminerali angewona kazibuthe, ngaleyo ndlela athole ukululama okuphelele, athuthukise izinga lokugxilisa ingqondo futhi anciphise umgijimi we-Tail. hlukanisa izinhlayiya ezincane. I-roller ithatha isakhiwo se-groove ukuvimbela ukuchezuka kwebhande.

Uchungechunge olubalulwe ngenhla lwemikhiqizo ekhiqizwe yi-Shandong Huate Magnetoelectric Technology Co., Ltd. lufanele ukuhlukaniswa kwamaminerali osayizi bezinhlayiyana ezahlukene. Zinokugxila kwazo ekwakhiweni kwesakhiwo somkhiqizo ukuze kuhlangatshezwane nezidingo zezinkomba zokuhlunga ezihlukene, futhi zisetshenziswe ngempumelelo. Emabhizinisini amaningi ezimayini, ibambe iqhaza elihle ekongeni amandla kanye nokunciphisa ukusetshenziswa kanye nokwenza ngcono ukusebenza kahle.

Amabhizinisi ezimayini kufanele akhethe umshini wokuhlukanisa uzibuthe ofanele izimo zebhizinisi lawo ngokwesimo sensimbi kanye nezimo zobuchwepheshe ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

Abakhiqizi bezinto zokusebenza kufanele baqhubeke bethuthukisa futhi baphelelise ukusebenza kwemikhiqizo yabo ngokwezidingo zokukhiqizwa kwamabhizinisi ezimayini, baxazulule izinkinga ezithile lapho besetshenziswa, bakhiqize imikhiqizo efaneleke kakhulu ezimbonini, futhi bakhuthaze ukuthuthukiswa kobuchwepheshe bemishini yokuhlukanisa kazibuthe.

Isikhathi sokuthumela: Mar-17-2021