Njengoba izwe lifaka ukubaluleka ekuvikelweni kwemvelo, njengohlobo lwemfucuza eqinile, indlela yokusebenzisa i-steel slag isibe yisihloko esibalulekile. Lesi sihloko sethula isixazululo esibanzi sobuchwepheshe sokugaywa kabusha kwe-slag yensimbi.Ubuchwepheshe bokucubungula okomile kufanele buqinisekise ukutholwa okusebenzayo kwezinsimbi ngakolunye uhlangothi kanye nokusetshenziswa okuphelele kwezinsalela zemfucuza ngakolunye. Izinyathelo ezilandelayo zokucubungula i-steel slag zichaziwe: Ukuchotshozwa okukhethiwe; ukuhlukaniswa kazibuthe kanye nendima yesigayo somshini omusha we-single-drive high-pressure roller ekusetshenzisweni okuphelele kwe-slag yensimbi; ukusetshenziswa kwemishini emisha kunganciphisa kakhulu izindleko zokuchotshozwa kwe-steel slag, ngaleyo ndlela kudale izinzuzo ezengeziwe zokusebenzisa i-slag yensimbi. Ukukhuthazwa kokusetshenziswa okuphelele kwe-slag yensimbi kuye kwadala amathuba okuba nokwenzeka. Ukugqugquzelwa kwalo mqondo obanzi embonini kudinga imizamo ehlanganyelwe yezinkampani ezikhiqiza insimbi, ochwepheshe bokucubungula izimbiwa kanye nezifundiswa, ukuqaliswa okuphelele kwesicelo, kanye neminyango yokumaketha nokukhuthaza.

Ukusetshenziswa kokwakhiwa kwe-steel slag

1) I-Slag yensimbi isetshenziselwa ukukhiqiza usimende nezixube zikakhonkolo. I-slag yensimbi iqukethe amaminerali asebenzayo afana ne-tricalcium silicate (C3S), i-dicalcium silicate (C2S) kanye ne-iron aluminate enezakhiwo ze-hydraulic cementing, ezihambisana nezici zikasimende. Ngakho-ke, ingasetshenziswa njengento eluhlaza kanye nengxube ye-cement yokukhiqiza usimende ongewona we-clinker, usimende omncane we-clinker. Usimende we-steel slag unezici ezinhle kakhulu ezifana nokumelana nokugqokwa, amandla aphezulu okuguquguquka, ukumelana nokugqwala kanye nokumelana nesithwathwa.

2) I-Slag yensimbi ithatha indawo yetshe elichotshoziwe kanye nokuhlanganisa okuhle. Itshe lensimbi elichotshoziwe le-slag linezinzuzo zamandla aphezulu, indawo embi kakhulu, ukumelana nokugqoka okuhle nokuqina, umthamo omkhulu, ukuzinza okuhle, kanye nenhlanganisela eqinile ne-asphalt. Uma kuqhathaniswa netshe elivamile elichotshoziwe, liphinde limelane nezici zokushisa okuphansi kokuqhekeka, ngakho-ke lingasetshenziswa kabanzi ekugcwaliseni ubunjiniyela bomgwaqo. I-steel slag, njenge-ballast yesitimela, inezici zokungaphazamisi umsebenzi wezokuxhumana wesistimu kaloliwe kanye nokuhamba kahle kukagesi. Ngenxa yokuthi i-steel slag inokungena kwamanzi okuhle nokugeleza kwamanzi, izingxenye ze-cementitious kuyo zingayenza ibe yizicucu ezinkulu. I-Slag yensimbi nayo ifaneleka ukwakhiwa komgwaqo emaxhaphozini nasemabhishi.

Njengamanje, indlela ejwayeleke kakhulu yokusebenzisa insimbi yasekhaya ukuchoboza insimbi ibe ngu-5mm ukushintsha isihlabathi somfula njengempahla yokwakha, noma ukugaya insimbi echotshoziwe ibe yimpushana ukuze isetshenziswe njengesithako sikasimende. I-Shandong Huate Magnetoelectric Technology Co., Ltd. yenze ucwaningo olunzulu mayelana nokusetshenziswa okuphelele kwe-slag yensimbi, yasebenzisa ngendlela entsha isigayo se-single-drive high-pressure roller ukuze kuchotshozwe kahle i-slag yensimbi, yathuthukisa ubuchwepheshe bokucubungula i-steel slag, futhi yazuza izinzuzo ezinhle zezomnotho. Isetshenziswe ngempumelelo ku-Pangang Mining kanye nebhizinisi elithile le-steel slag e-Lianyungang.

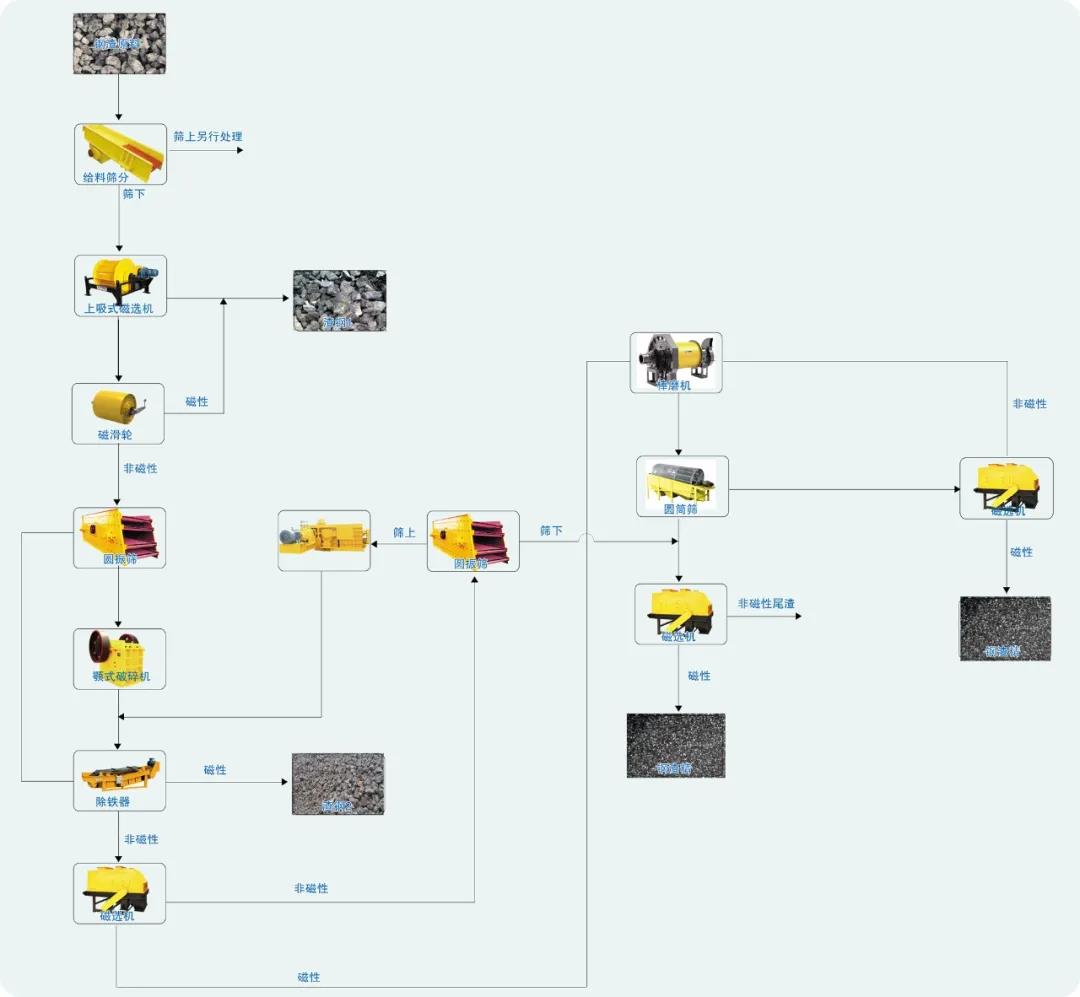

Inqubo yokukhiqiza yendabuko ye-steel slag imi kanje:

I-1) Izingcezu ezinkulu zichotshozwa nge-crusher yomhlathi kuya ku-50, futhi insimbi kazibuthe ihlukaniswa ne-pulley magnetic.

2) Setha usayizi wokuhlukanisa wensimbi ku-+45 mm. I-0-45 mm esele ivame ukusetshenziswa njengokwakhiwa komgwaqo kanye nezinto zokugcwalisa. Ukuze ukwandise inani layo lesicelo, i-slag yensimbi ingahlukaniswa ibe yi-0-4, 4-8 namanye amamaki ahlukene. Ubuchwepheshe budinga imali encane kanye nezindleko eziphansi zokusebenza. Kodwa-ke, ngaphezu kwe-50% yokuqukethwe kwensimbi ku-slag kugxilwe ku--10 mm force, ngakho-ke lobu buchwepheshe buzobangela ukulahlekelwa okuningi kwensimbi, kodwa okuqukethwe kwensimbi esindayo kuzokwanda.

Ngakho-ke, ukugaya okuhle okumanzi kuye kwasetshenziswa kabanzi ikakhulukazi ku-slag ekhiqizwa ekwenziweni kwensimbi ephezulu ye-alloy equkethe i-high-grade Cr, i-Ni, i-Mo, njll. Izinqubo ezijwayelekile zihlanganisa ukuchotshozwa kanye nezinyathelo ezimbili zokugaya kahle (i-rod mill/ball mill. ). Njengoba insimbi ene-ductility akulula ukuyigaya, ukuhlukaniswa kwensimbi nensimbi ye-slag kungafinyelelwa ngokuhlunga noma ukuhlukaniswa. Ubuhle bengxenye yamaminerali ye-slag ngokuvamile bungaphezu kwama-95% nangaphansi kuka-0.2mm. Izinga lokubuyisela insimbi yale nqubo lidlula i-95%, futhi isivuno sokugxila kwensimbi esikhiqizwayo singama-90 kuya ku-92%. Ngokombono wokuhlukanisa insimbi ne-slag, le nqubo ingashiwo ukuthi iyinqubo engcono kakhulu.

Ukungalungi okuyinhloko kwale nqubo ukuthi i-slag yensimbi ehlukanisiwe iyi-slurry enezinhlamvu ezinhle. Ngenxa yokuthi inqubo iyinqubo emanzi, kunzima ukufaka isicelo ekwakhiweni kwesakhiwo. Ngakho-ke, izinto eziningi ze-slag zensimbi ezisele ngemuva kokuqokwa kwensimbi zilahliwe, futhi lokhu kuvame ukubangelwa izindleko eziphakeme zokumisa okumanzi kanye nemingcele yezomthetho emhlabeni jikelele. Noma yisiphi isicelo senani eliphakeme sidinga ezinye izindlela zokwelapha udaka olumanzi (ukoma, ukujiya, njll.).

Ngokuvamile ukukhetha kufanele kwenziwe phakathi kwezinga lokutholwa kwensimbi noma ukutholakala kwe-slag esele. Ngokuvamile, lokhu kukhetha kuncike enanini lensimbi etholiwe.

Izinqubo ezijwayelekile kulesi sigaba zimi kanje:

Izingcezu ezinkulu zichotshozwa nge-crusher yomhlathi ukuya ku-50, futhi insimbi kazibuthe ihlukaniswa ne-pulley magnetic.

-50 insimbi slag ichotshozwa ngesando crusher noma cone crusher, impact crusher, sieved ngokusebenzisa multi-layer sieve, -20-10 grit umkhiqizo ungasetshenziswa njengetshe, -10–1 grit umkhiqizo ungasetshenziswa njengesihlabathi esihle.

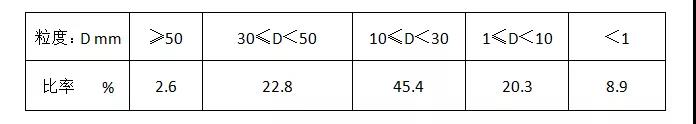

Ithebula I

Ukuhlaziywa kosayizi wezinhlayiyana zokuphakelayo okungu-50mm kucrusher isando

-10 okusanhlamvu i-slag yensimbi igaywa ibe yibhola elomile libe yimpushana emihle engu- -200 mesh, bese kusetshenziswa isihlukanisi sikazibuthe sempushana eyomile kagesi ukuze kukhishwe insimbi njengesithako sikasimende.

Isikhathi sokuthumela: Apr-12-2021