Njengenye yezinsimbi zakuqala nezisetshenziswa kakhulu emhlabeni, insimbi iyinsimbi esetshenziswayo ebalulekile ekukhiqizeni insimbi nensimbi.Njengamanje, izinsiza zensimbi ziyancipha, ezibonakala ngengxenye ephezulu yensimbi engenasisindo uma iqhathaniswa ne-ore ecebile, i-ore ehlobene kakhulu, kanye nokwakheka kwe-ore eyinkimbinkimbi.I-ayoni ivame ukukhishwa ku-ore yayo, eyaziwa ngokuthi i-hematite noma i-magnetite, ngenqubo ebizwa ngokuthi i-iron ore beneficiation.Izinyathelo ezithile ezihilelekile ekukhishweni kwezimboni zensimbi zingahluka kuye ngohlobo lwensimbi nemikhiqizo efunekayo, kodwa inqubo evamile ngokuvamile ihilela izigaba ezilandelayo:

Izimayini

Amadiphozithi ensimbi aqala ukubonwa ngemisebenzi yokuhlola.Uma idiphozithi esebenzayo isitholakele, insimbi ikhishwa emhlabathini kusetshenziswa amasu okumba afana nomgodi ovulekile noma izimayini ezingaphansi komhlaba.Lesi sigaba sokuqala sibalulekile njengoba sibeka inkundla yezinqubo zokukhipha okulandelayo.

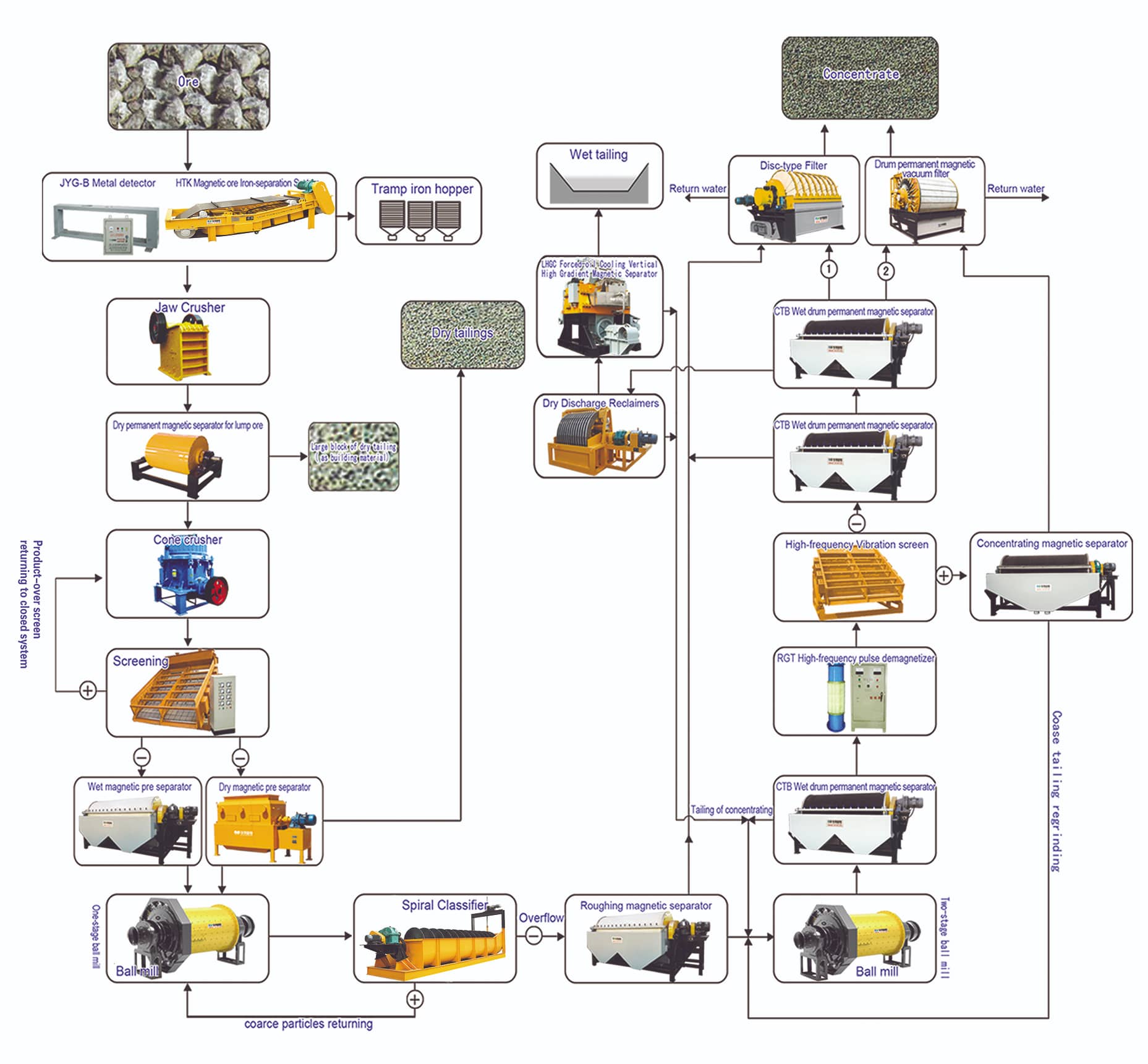

Ukuchoboza nokugaya

I-ore ekhishiwe ibe isichotshozwa ibe izingcezu ezincane ukuze kube lula ukucutshungulwa okuqhubekayo.Ukuchotshozwa ngokuvamile kwenziwa kusetshenziswa ama-crusher emihlathini noma ama-cone crushers, futhi ukugaya kwenziwa kusetshenziswa izigayo zokugaya ezizenzakalelayo noma izigayo zebhola.Le nqubo inciphisa insimbi ibe yimpushana, okwenza kube lula ukuyiphatha nokuyicubungula ezigabeni ezilandelayo.

Ukuhlukaniswa Kwamagnetic

Insimbi ngokuvamile iqukethe ukungcola noma amanye amaminerali okudingeka asuswe ngaphambi kokuba asetshenziswe ekukhiqizeni insimbi nensimbi.Ukuhlukaniswa kwamagnetic kuyindlela evamile esetshenziswa ukuhlukanisa amaminerali kazibuthe kulawo angewona azibuthe.Ozibuthe abanamandla, njengesihlukanisi sikazibuthe se-Huate, basetshenziselwa ukuheha nokuhlukanisa izinhlayiya zensimbi ku-ganggue (izinto ezingadingeki).Lesi sinyathelo sibalulekile ekwenzeni ngcono ukuhlanzeka kwensimbi.

Ukuhlomula

Isinyathelo esilandelayo ukuhlomula kwe-ore, lapho umgomo uwukwandisa okuqukethwe kwensimbi ngamasu ahlukahlukene.Le nqubo ingase ihlanganise ukugeza, ukuhlola, kanye nezindlela zokuhlukanisa amandla adonsela phansi ukuze kukhishwe ukungcola futhi kuthuthukiswe ikhwalithi yensimbi.Ukuhlomula kungahlanganisa nokuntanta, lapho amakhemikhali engezwa ensimbini ukuze enze izinhlayiya zensimbi zintante futhi zihlukane nakho konke okunye.

Pelletizing noma Sintering

Lapho insimbi isizuziwe, kungase kudingeke ukuba izinhlayiya ezinhle zihlanganiswe zibe ezinkulu ukuze zicutshungulwe kahle.I-Pelletizing ihlanganisa ukwenza ama-pellets amancane ayindilinga ngokuwisa insimbi ngezithasiselo ezifana ne-limestone, i-bentonite, noma i-dolomite.I-Sintering, ngakolunye uhlangothi, ihlanganisa ukushisisa izinhlawulo ze-ore kanye nokugeleza nomoya we-coke ukwakha inqwaba ehlanganiswe kancane eyaziwa ngokuthi i-sinter.Lezi zinqubo zilungiselela insimbi isinyathelo sokugcina sokuyikhipha ngokwenza ngcono izici zayo ezibonakalayo nezici zokuphatha.

Ukuncibilika

Isinyathelo sokugcina senqubo yokukhipha ukuncibilika, lapho insimbi yensimbi ishiswa esithandweni somlilo kanye ne-coke (uphethiloli we-carbonaceous) kanye ne-limestone (esebenza njenge-flux).Ukushisa okunamandla kubhidliza itshe lensimbi libe insimbi encibilikisiwe, eqoqana phansi esithandweni, kanye ne-slag, entanta phezulu bese ikhishwa.Insimbi encibilikisiwe ibe isijikijelwa emimoyeni ehlukahlukene, njengama-ingots noma amabhilidi, futhi iphinde icutshungulwe ukuze kutholwe imikhiqizo yensimbi nensimbi efunekayo.

Kubalulekile ukuqaphela ukuthi idiphozithi yensimbi ehlukene kanye nezitshalo zokucubungula zingase zibe nokuhluka ezinqubweni ezithile ezisetshenziswayo, kodwa imigomo iyonke ihlala ifana.Ukukhishwa kwensimbi ensimbi kuyinqubo eyinkimbinkimbi futhi enezinyathelo eziningi edinga ukuphathwa ngokucophelela kwezinsiza nobuchwepheshe.Ukufakwa kwemishini ethuthukisiwe efana ne-Huate magnet separator kuthuthukisa ukusebenza kahle kanye nekhwalithi yenqubo yokuhlukanisa, ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso ezidingekayo zokukhiqiza insimbi nensimbi.

Isikhathi sokuthumela: Jul-08-2024