【01 Uhlolojikelele】

I-HUATE MAGNET

Imithombo yensimbi yaseShayina inothile ngezinqolobane nezinhlobo ezahlukene, kodwa kunensimbi eningi ethambile, insimbi engacebe kakhulu, kanye nosayizi wokusanhlamvu oshunyekwe kahle. Kukhona insimbi encane kakhulu engasetshenziswa ngokuqondile, futhi inani elikhulu le-ore lidinga ukucutshungulwa ngokuzuzisa. Isikhathi eside, kuye kwaba nzima nakakhulu ukuhlomula kuma-ores akhethiwe, isilinganiso se-beneficiation siya ngokuya sikhula, inqubo kanye nemishini kuya ngokuya kuba nzima nakakhulu, ikakhulukazi izindleko zokugaya zikhombisa umkhuba okhulayo. Ngakho-ke, kubaluleke kakhulu ukunciphisa ukusetshenziswa kwamandla kwenqubo yokugaya ohlelweni lokuhlomula. Njengamanje, izitshalo zokugqoka ngokuvamile zisebenzisa izinyathelo ezifana nokuchotshozwa okwengeziwe nokugaya okuncane, ukukhethwa kwangaphambili nokulahla ngaphambi kokugaya, njll, okuthole imiphumela ephawulekayo.

Ezindaweni ezinokuntuleka kwemithombo yamanzi, amanzi okuthuthukiswa kwezimayini awanakuqinisekiswa, okwenza ukuhlukaniswa okumanzi kwezimbiwa kungenzeki. Ngakho-ke, kulezi zindawo, indlela eyomile yokukhethwa kwangaphambili izocatshangelwa kuqala ngokulahlwa kwemfucuza.

Ukuchotshozwa okucolisekileyo nokucwebezelisa okomile ngosayizi wezinhlayiyana ezingama-20-0 mm, kanye nokupholishwa okomile kwemikhiqizo echotshoziwe yomshini wokugaya i-high-pressure roller esetshenziswa kabanzi okwamanje, isakhiwo semishini ekhethiwe sihlukile. Isihlukanisi kazibuthe sinezici zokulondoloza indawo yokufaka, umthamo omkhulu wokucubungula, izinga eliphezulu le-scrap kanye nezinga eliphezulu lokubuyisela, futhi uthole imiphumela emihle ezinhlelweni ezisebenzayo.

[02 Isimiso sesakhiwo nomthelela wokusetshenziswa]

I-HUATE MAGNET

Umshini wokukhethwa kwangaphambi kokukhetha onezigubhu ezintathu ohlangene uvame ukuba nezakhiwo ezimbili: okukodwa okumahwashazayo nokushanela okubili, nokushodayo okukodwa nokuqeda okubili. Isakhiwo sokwakheka kwezigxobo kazibuthe siklanywe ngokuhambisana nezidingo zezinkomba zokuhlunga amaminerali, kucatshangelwa izinga lokunqatshelwa kanye nezinga lokuthola kabusha, futhi ngokuhlaziywa kokulingisa, ukuklama okukodwa kuya kokukodwa.

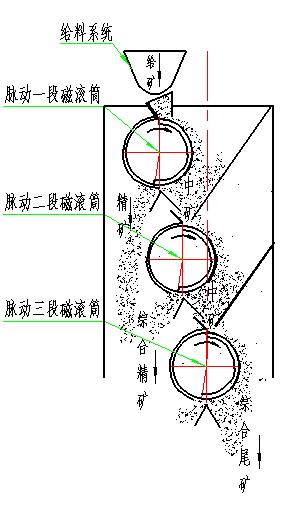

1. Umgomo wokusebenza wokushanela okukodwa okuqinile kanye nokubili

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela. Insimbi ihlukaniswa yisigubhu sokuqala ukukhipha ingxenye ye-concentrate. Izisila zeshubhu lokuqala zingena eshubhuni lesibili ukuze zishanelwe, izisila zeshubhu lesibili zingena eshubhuni lesithathu bese kuthi imisila yeshubhu lesithathu ingene eshubhu lesithathu. Ukuze uthole ama-tailings okugcina, ukugxila kwemiphongolo yokuqala, yesibili neyesithathu kuhlanganiswe ekugxilweni kokugcina. Umgomo wokusebenza wokuskena okukodwa okubili okumaholoholo ukhonjiswe kuMfanekiso 1.

▲Umdwebo 1 Umdwebo wohlelo wesimiso sokusebenza sokushanela okukodwa okumaholo nokubili

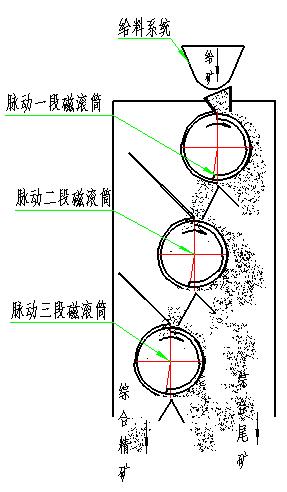

2. Umgomo wokusebenza wenhlawulo eyodwa kanye nenhlawulo emibili

Izinto ezisetshenziswayo zingena etsheni ngomshini wokuphakela. Ngemva kokuba i-ore ihlukaniswe yisigubhu sokuqala, ukugxila kungena emgqonyeni wesibili ukuze kuhlukaniswe okuqhubekayo, futhi ukugxila emgqonyeni wesibili kungena emgqonyeni wesithathu ukuze kuhlukaniswe. I-concentrate emgqonyeni wesithathu yi-concentrate yokugcina. Izisila zamasilinda wesibili nowesithathu zihlanganiswa zibe yizinsalela zokugcina. Umgomo wokusebenza wenhlawulo eyodwa emaholoholo nezimbili uboniswa kuMfanekiso 2.

▲ Umfanekiso 2 Umdwebo wohlelo lwesimiso sokusebenza sokumahhadla nokubili kwenhlawulo

3 .Indawo yohlelo lokusebenza yochungechunge lwe-MCTF enezigubhu ezintathu eziphephula isihlukanisi esinozibuthe esomile

▲Umdwebo 3 Isiza sokufaka isicelo se-3MCTF enezigubhu ezintathu eziphephula isihlukanisi esinozibuthe esomile esinomshini wokuphakelayo.

Ikhasimende elisesithombeni esingenhla lisebenzisa isihlukanisi sangaphambili esinezigubhu ezintathu ezingu-1030 esizeni. Ububanzi besigubhu buyi-1000mm nobude bungama-3000mm. Isakhiwo senqubo siwukugqashuka okukodwa kanye nokushanela okubili. Insimbi kazibuthe ingu-0.6%, futhi izinga le-scrap lingaphezu kuka-30%, elifinyelela umphumela olindelekile.

【03 Isizinda sokukhiqiza】

I-HUATE MAGNET

▲Isizinda sokukhiqiza sesihlukanisi esinozigqoko esinezigubhu ezintathu esomile

Ububanzi bezinsizakalo zobuchwepheshe ze-Huate Mineral Processing Engineering Design Institute

①Ukuhlaziywa kwezinto ezijwayelekile kanye nokutholwa kwezinto zensimbi.

②Ukulungiswa nokuhlanzwa kwamaminerali angewona awensimbi njengesiNgisi, itshe elide, i-fluorite, i-fluorite, i-kaolinite, i-bauxite, i-leaf wax, ne-baryrite.

③Ukuzuza kwezinsimbi ezimnyama njengensimbi, i-titanium, i-manganese, i-chromium ne-vanadium.

④ Ukuzuza kwamaminerali abuthakathaka amaminerali kazibuthe njenge-ore ye-tungsten emnyama, i-tantalum niobium ore, ihalananda, igesi kagesi, nefu elimnyama.

⑤ Ukusetshenziswa okuphelele kwezisetshenziswa zesibili ezifana nezinsila ezihlukahlukene kanye ne-smelting slag.

⑥ Kukhona i-ore-magnetic, esindayo kanye ne-flotation ehlanganisiwe yokuzuza kwensimbi eyinsimbi.

⑦Ukuhlungwa kwezinzwa ezihlakaniphile zamaminerali ensimbi nangewona awensimbi.

⑧ Isivivinyo sokukhetha esiqhubekayo se-semi-industrialized.

⑨ Ukucutshungulwa kwempushana ecwebezelayo njengokuchotshozwa kwezinto, ukugaywa kwebhola nokuhlukaniswa ngezigaba.

⑩ Amaphrojekthi we-EPC turnkey afana nokuchotshozwa, ukukhetha kwangaphambilini, ukugaya, ukuhlukaniswa kwamagnetic (okusindayo, okuntantayo), isihlenga esomile, njll.

Isikhathi sokuthumela: Jul-25-2022