Enqubweni yokuhlukaniswa kazibuthe kwe-magnetite, ngenxa ye-agglomeration kazibuthe, kulula ukukhiqiza "i-inclusions magnetic" kanye "ne-non-magnetic inclusions", okuthinta kakhulu izinga lokugxila. I-Walt iyisizukulwane esisha semishini yokuhlukanisa kazibuthe ebuthakathaka. Icubungula ngokucophelela izinkambu zamandla abanzi njengamandla kazibuthe, amandla adonsela phansi, amandla adonsela phansi, amandla e-centrifugal, njll. Kuhlanganiswe, imingcele yokusebenza ilungiswa ngokuzenzakalelayo ngokuvumelana nezakhiwo ze-ore, ezinganciphisa ngempumelelo okuqukethwe kokungcola okufana ne-silicon, i-phosphorus. , kanye nesibabule ku-ores kazibuthe, futhi uthole i-high-grade magnetite igxila kanye nemikhiqizo ephakathi efana nokugxila enqubweni yokuhlukanisa kazibuthe, efanelekile kusengaphambili. I-concentrate yokugcina ifanele ukusebenza kokusizakala kwe-concentrator kazibuthe, okuvula indlela entsha yokuthi insimbi yezwe lami igxile ekuqaliseni isu “lokwenza ngcono kanye nokunciphisa ukungcola”.

Isimiso sokusebenza

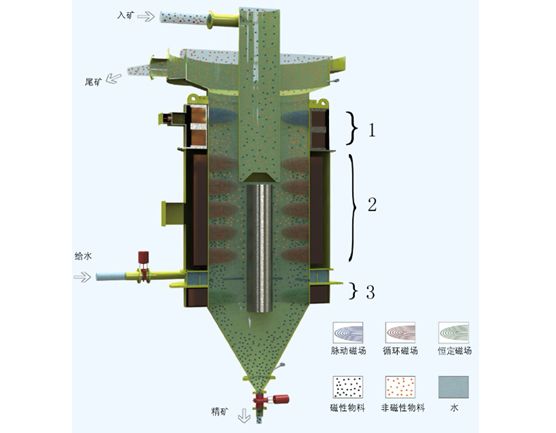

Insimbi ifakwa phakathi nendawo engenhla yomshini wokukhipha insimbi ngensimbi yokuphakela insimbi kanye nepayipi lokuphakela insimbi, futhi ikhukhulwe ngamanzi ashawayo. Phakathi kwamakhoyili amabili nalapho ikhoyili icishwa, njengoba amandla kazibuthe ashona phansi entekenteke kakhulu, ayagundwa futhi ahlakazwe ukugeleza kwamanzi ajikelezayo phezulu ngesivinini esiphezulu, ukuze i-ganggue eyodwa, i-ore slime kanye nezinto eziphilayo ezihlangene zixubane kuwo. , ikakhulukazi izinto eziphilayo ezimpofu ezihlangene. Ibhande eligijimayo liphezulu, futhi ngaphansi kwesenzo sokugeleza kwamanzi azungezayo anamandla abheke phezulu, akhuphukela onqenqemeni oluchichimayo futhi akhishwe ukuze abe imisila ikakhulukazi eyakhiwe imizimba ehlangene.

Umgomo wokusebenza womshini wokukhetha i-electromagnetic panning

Amaminerali kazibuthe ku-ore adonswa yinkundla kazibuthe ekhiqizwe ikhoyili kagesi, futhi izinhlayiya zensimbi kazibuthe ziba ama-dipoles kazibuthe, futhi ama-dipoles amaningi kazibuthe adonselana ukuze akhe amaketanga kazibuthe.Lapho ikhoyili icinywa, ukugeleza okuzenzakalelayo ukuxhunyaniswa kokucisha kwamandla kuhlakazwa ngokugcwele ngokugunda kwe-axial ngaphansi kwesenzo sokugeleza kwamanzi ajikelezayo ngesivinini esikhulu futhi akhuphukayo.Inqubo engenhla iyaphindwa lapho ikhoyili elandelayo inikwa amandla futhi iphelelwa amandla. Le nqubo yenziwa izikhathi eziningi, ukuze izinto kazibuthe zingakhethwa izikhathi eziningi emshinini we-elutriation ukuze kutholwe i-high-grade magnetite concentrate, futhi ngesikhathi esifanayo, okuqukethwe kokungcola okufana ne-SiO2 nakho kuyancipha.

Inqubo yokulawula yomshini wokuwasha

Umshini we-elutriation usebenzisa ukulawulwa kwe-impulse emibili, okungukuthi, ukugxila kokuchichima kanye nokugxilwa kokugeleza okungaphansi kuyizinjongo zokulawula.Ukugxiliswa kokuchichima kulawulwa ubukhulu bamandla kazibuthe, futhi ukugxiliswa kokugeleza kulawulwa ngokuvula phansi. I-valve.Kusistimu yokulawula, ngokusetha amanani okuhlosiwe okugxiliswa kokuchichima nokugxilisa ukugcwala kwamanzi, isistimu yokulawula isebenzisa i-algorithm yokulawula ehlakaniphile yokulawula amandla kazibuthe kanye nokuvulwa kwe-valve engezansi ukuze kugcinwe inani eliqondiwe ngaphakathi kwebanga elithile lokusebenza. .

Lapho inani lokuphakela insimbi lingazinzile, isistimu yokulawula izolungisa ngokuzenzakalelayo i-valve engezansi ngokuvumelana noshintsho lokuhlushwa kwamanzi angaphansi kwamanzi ngaphakathi komshini we-elutriation, ukuze i-magnetic medium ngaphakathi komshini we-elitriation ihlale ingashintshile futhi igcine indawo yokuhlunga ezinzile; ukunikezwa kwamanzi akuzinzile, uhlelo lokulawula lulungisa ukuqina kwamandla kazibuthe ngokusho kokushintsha kokuhlushwa okuchichimayo komshini wokuwasha ukuze kuqinisekiswe ukuzinza kwenkomba yokugxila.

Umshini ozenzakalelayo wokuphena kanye nokukhetha kuka-electromagnetic usebenzisa indlela yokulawula ethuthukisiwe ye-PID-automatic optimization, engadingi umsebenzi owenziwa ngesandla futhi ehlala isebenza esimweni esihle kakhulu. Ngokusebenzisa ubuchwepheshe be-inthanethi Yezinto, imingcele yokusebenza idluliselwa endaweni yesikhulumi samafu esikude, kanye ne-elekthronikhi. amafayela asungulelwa okokusebenza ukuze alawule umjikelezo wokuphila wonke; Ochwepheshe bokucubungula amaminerali enkampani yethu bangalungisa bekude imingcele yokucubungula amaminerali omshini wokuwasha ngokusebenzisa inkundla yokuqapha ekude ukuze bakhonze kangcono abasebenzisi.

Ikesi lesicelo lomshini wokukhetha i-electromagnetic panning

Isikhathi sokuthumela: Mar-21-2022