I-Kaolin ineziqiwu eziningi ezweni lami, futhi izindawo ezigciniwe zokwakheka komhlaba ezifakazelwe zingamathani ayizigidi eziyizinkulungwane ezintathu, ezisatshalaliswa ikakhulukazi eGuangdong, eGuangxi, eJiangxi, eFujian, eJiangsu nakwezinye izindawo. Ngenxa yezizathu ezihlukene zokwakheka kwe-geological, ukwakheka kanye nokwakheka kwe-kaolin evela ezindaweni ezikhiqizayo ezahlukahlukene nakho kuhlukile. I-Kaolin iwuhlobo lwe-1:1 ye-silicate enezingqimba, eyakhiwe i-octahedron ne-tetrahedron. Izingxenye zayo eziyinhloko yi-SiO2 ne-Al203. Futhi iqukethe inani elincane le-Fe203, Ti02, MgO, CaO, K2O ne-Na2O, njll. I-Kaolin inezakhiwo eziningi ezinhle kakhulu zomzimba namakhemikhali kanye nezici zenqubo, ngakho-ke isetshenziswa kakhulu kumakhemikhali kaphethiloli, ukwenza iphepha, izinto ezisebenzayo, okokugqoka, izitsha zobumba, izinto ezimelana namanzi, njll. Ngokuthuthuka kwesayensi nobuchwepheshe besimanje, ukusetshenziswa okusha kwe-kaolin. zilokhu zanda, futhi seziqala ukungena ezindaweni eziphakeme, ezinembayo nezisezingeni eliphezulu. I-Kaolin ore iqukethe inani elincane (imvamisa u-0.5% kuya ku-3%) wamaminerali ensimbi (i-iron oxides, i-ilmenite, i-siderite, i-pyrite, i-mica, i-tourmaline, njll.), efaka umbala ku-kaolin futhi ithinte ubumhlophe bayo bokucwenga nezinye izakhiwo zikhawulela isicelo. kwe kaolin. Ngakho-ke, ukuhlaziya ukwakheka kwe-kaolin kanye nocwaningo lobuchwepheshe bayo bokususa ukungcola kubaluleke kakhulu. Lokhu kungcola okunemibala kuvame ukuba nezinto ezibuthakathaka kazibuthe futhi kungasuswa ngokuhlukana kazibuthe. Ukuhlukaniswa kwamagnetic kuyindlela yokuhlukanisa izinhlayiya zamaminerali endaweni kazibuthe ngokusebenzisa umehluko kazibuthe wamaminerali. Kumaminerali kazibuthe abuthakathaka, inkambu kazibuthe ene-gradient ephezulu iyadingeka ukuze kuhlukaniswe kazibuthe.

Isakhiwo nomgomo wokusebenza we-HTDZ isihlukanisi esinozibuthe esine-gradient ephezulu

1.1 Isakhiwo se-electromagnetic slurry high gradient separator kazibuthe

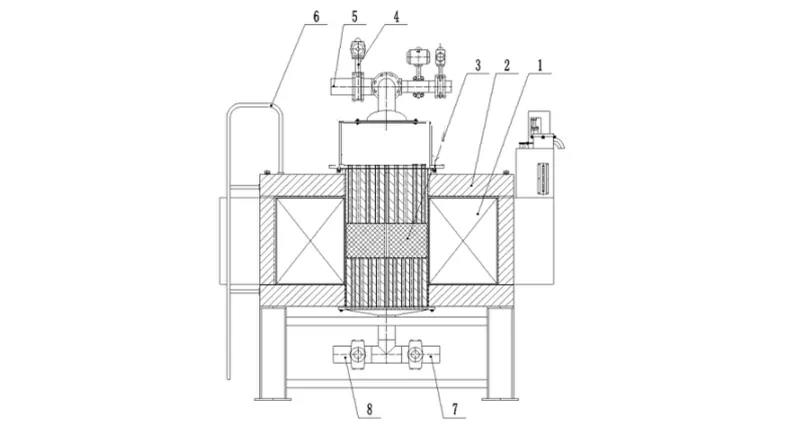

Umshini ikakhulukazi wakhiwe ifreyimu, ikhoyili ye-excitation epholile kawoyela, isistimu kazibuthe, i-separation medium, isistimu yokupholisa ikhoyili, isistimu yokuguquguquka, i-ore inlet kanye nesistimu yokukhipha, uhlelo lokulawula, njll.

Umfanekiso 1 Umdwebo wesakhiwo sesihlukanisi sozibuthe esine-gradient ephezulu sodaka lukagesi

1- Ikhoyili evusa amadlingozi 2- Isistimu kaMagnetic 3- Ukuhlukanisa okuphakathi 4- Ivalvu yomoya 5- Ipayipi lokuphuma kwePulp

6-Escalator 7-Inlet ipayipi 8-Slag discharge pipe

1.2 Izici zobuchwepheshe ze-HTDZ electromagnetic slurry high gradient separator kazibuthe

◎Ubuchwepheshe bokupholisa uwoyela: Amafutha okupholisa avaliwe ngokugcwele asetshenziselwa ukupholisa, ukushintshaniswa kokushisa kwenziwa kusetshenziswa isimiso sokushintshaniswa kokushisa kwamafutha-amanzi, futhi kwamukelwa iphampu yamafutha e-disc-flow disc enkulu. Amafutha okupholisa anejubane elisheshayo lokujikeleza, amandla okushintshana okushisa aqinile, ukukhuphuka kwezinga lokushisa lekhoyili eliphansi, namandla kazibuthe aphezulu.

◎Ukulungiswa kwamanje kanye nobuchwepheshe bamanje bokuzinza: Ngemojula yokulungisa, ukukhishwa kwamanje okuzinzile kuyabonakala, futhi amandla ashukumisayo alungiswa ngokuvumelana nezici zezinto ezihlukahlukene ukuze kuqinisekiswe amandla kazibuthe azinzile futhi kuzuzwe inkomba engcono kakhulu yokuhlomula.

◎Ubuchwepheshe bezibuthe bomzimba obusebenza kahle kakhulu obusebenza ngezinsimbi ezinkulu: Sebenzisa izikhali zensimbi ukugoqa ikhoyili engenalutho, dweba ukwakheka kwesekethe kazibuthe kagesi enengqondo, unciphise ukugcwala kwezikhali zensimbi, unciphise ukuvuza okuguquguqukayo kazibuthe, futhi wakhe amandla ensimu ephezulu endaweni yokuhlela.

◎Ubuchwepheshe bokuhlukaniswa kwezigaba ezintathu ze-Solid-liquid-gas: Izinto ezisegunjini lokuhlukanisa zingaphansi kwe-buoyancy, amandla adonsela phansi uqobo, namandla kazibuthe ukuze kuzuzwe umphumela ofanele wokuzuza ngaphansi kwezimo ezifanele. Ukuhlanganiswa kwamanzi okukhipha kanye nomfutho womoya ophezulu kwenza ukuhlanza okuphakathi nendawo kuhlanzeke.

◎Ubuchwepheshe obusha be-spikysstainless stainless uzibuthe kanye nobuchwepheshe bezinto ezibonakalayo kazibuthe: okuphakathi kokuhlunga kusebenzisa insimbi yensimbi, inetha lemidiya elimise okwedayimane, noma inhlanganisela yoboya bensimbi kanye nemidiya emise okwedayimane. Le medium ihlanganisa izici zemishini, kanye nocwaningo kanye nokuthuthukiswa kwensimbi engagqwali engagqoki, i-gradient induction induction magnetic inkulu, kulula ukuthwebula amaminerali kazibuthe abuthakathaka, ukuqina kuncane, kanti okuphakathi kulula ukuwasha lapho itshe lensimbi lichithwa.

1.3 Ukuhlaziywa kwesimiso sezisetshenziswa kanye nokuhlaziywa kokusabalalisa indawo kazibuthe

1.3.1Umgomo wokuhlunga uthi: Kukhoyili ye-armored, inani elithile loboya bensimbi obungenasici obuzibuthe (noma insimbi enwetshiwe) lifakwa. Ngemva kokuba ikhoyili ijabulile, uboya bensimbi obungenazibuthe obusebenza ngozibuthe busebenza uzibuthe, futhi kukhiqizwa insimu kazibuthe engalingani kakhulu endaweni, okungukuthi i-High-gradient magnetizing magnetic field, lapho impahla ye-paramagnetic idlula uvolo wensimbi ethangini lokuhlunga, izothola amandla kazibuthe ngokulingana nomkhiqizo wensimu kazibuthe esetshenzisiwe kanye ne-gradient yamagnetic field, futhi izokhangiswa phezu koboya bensimbi, esikhundleni sezinto ezingezona kazibuthe ezidlula inkambu kazibuthe ngokuqondile. Igeleza ingene ethangini lomkhiqizo elingewona uzibuthe ngevalvu engeyona kazibuthe kanye nepayipi. Lapho izinto ezinozibuthe ezibuthakathaka eziqoqwe uboya bensimbi zifinyelela ezingeni elithile (ezinqunywe yizidingo zenqubo), yeka ukondla insimbi. Nqamula isiphakeli samandla esivusa amadlingozi bese ususa izinto kazibuthe. Izinto kazibuthe zigelezela kuthangi lomkhiqizo kazibuthe ngevalvu kazibuthe nepayipi. Bese wenza umsebenzi wesikole wesibili, bese uphinda lo mjikelezo.

1.3.2Ukuhlaziywa kokusabalalisa inkambu kazibuthe: Sebenzisa isofthiwe yesici esinqunyelwe esithuthukisiwe ukuze ulingise ngokushesha imephu yefu yokusabalalisa insimu kazibuthe, ufinyeze umjikelezo womklamo nokuhlaziya; zamukele idizayini ethuthukisiwe yokunciphisa ukusetshenziswa kwamandla kwemishini nokunciphisa izindleko zabasebenzisi; thola izinkinga ezingaba khona ngaphambi kokukhiqizwa komkhiqizo , Khulisa ukwethembeka kwemikhiqizo namaphrojekthi; belingisa izinhlelo ezihlukahlukene zokuhlola, ukunciphisa isikhathi sokuhlola kanye nezindleko;

Izici zokunyakaza kwamaminerali

2.1 Ukuhlaziya ukunyakaza kwezinto

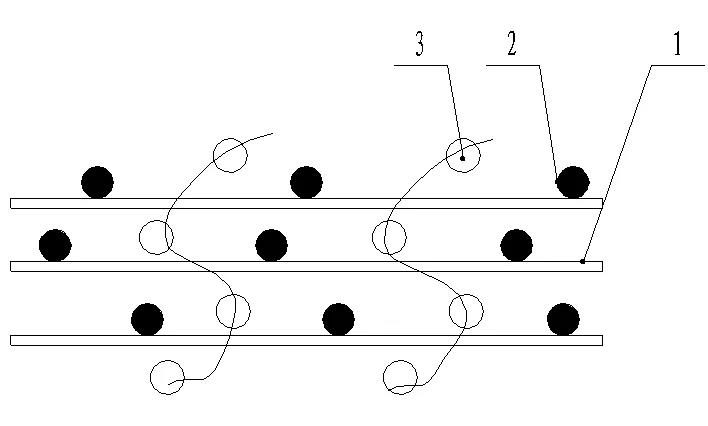

I-HTDZ high gradient separator kazibuthe ifanele ukuphakela okuphansi lapho ihlungwa i-kaolin. Izinto zokusebenza zamukela uboya bensimbi obungagqwali obunezingqimba eziningi (noma insimbi enwetshiwe) njengendawo yokuhlunga, ukuze umkhondo wezinhlayiya zensimbi ungajwayelekile eziqondisweni eziqondile nezivundlile. Ukunyakaza kwejika lezinhlayiya zamaminerali kuboniswe kuMfanekiso 1. Ngakho-ke, ukwandisa isikhathi sokugijima kanye nebanga lamaminerali endaweni yokuhlukanisa kuyasiza ekukhangiseni okugcwele kwamagnetic abuthakathaka. Ngaphezu kwalokho, izinga lokugeleza kwe-slurry, amandla adonsela phansi kanye ne-buoyancy ngesikhathi senqubo yokuhlukanisa kusebenzisana nomunye nomunye. Umphumela uwukugcina izinhlayiya ze-ore zisesimweni esixekethile ngaso sonke isikhathi, ukunciphisa ukunamathela phakathi kwezinhlayiya ze-ore, nokuthuthukisa ukusebenza kahle kokukhipha insimbi. Thola umphumela omuhle wokuhlunga.

Umfanekiso 4 Umdwebo wohlelo lokunyakaza kwamaminerali

1. Inethiwekhi yemidiya 2. Izinhlayiya zikazibuthe 3. Izinhlayiya ezingezona uzibuthe.

2. Imvelo yensimbi eluhlaza kanye nenqubo eyisisekelo yokuzuza

2.1 Izici ze-kaolin mineral material ethile e-Guangdong:

Amaminerali e-ganggue e-kaolin endaweni ethile e-Guangdong ahlanganisa i-quartz, i-muscovite, i-biotite ne-feldspar, kanye nenani elincane elibomvu ne-limonite. I-Quartz inothiswe kakhulu kusayizi wokusanhlamvu okungu-+0.057mm, okuqukethwe kwamaminerali e-mica kanye ne-feldspar kucebile kusayizi wokusanhlamvu ophakathi (0.02-0.6mm), futhi okuqukethwe kwe-kaolinite kanye nenani elincane lamaminerali amnyama kancane kancane likhula njengoba okusanhlamvu. usayizi uyancipha. , i-Kaolinite iqala ukunothiswa ku--0.057mm, futhi ngokusobala inothiswe ngosayizi -0.020mm.

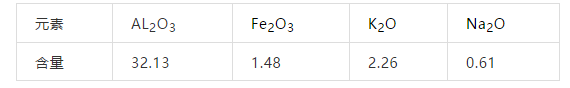

Ithebula 1 Imiphumela yokuhlaziya yezinto eziningi ze-kaolin ore%

2.2 Izimo eziyinhloko zokuhlomula ezisebenza ekuhloleni kokuhlola kwesampula encane

Izici eziyinhloko ezithinta inqubo yokuhlukanisa kazibuthe yesihlukanisi esinodaka kazibuthe esine-gradient ephezulu yizinga lokugeleza kodaka, isizinda samandla kazibuthe, njll. Izimo ezimbili eziyinhloko ezilandelayo ziyahlolwa kulolu cwaningo lokuhlola.

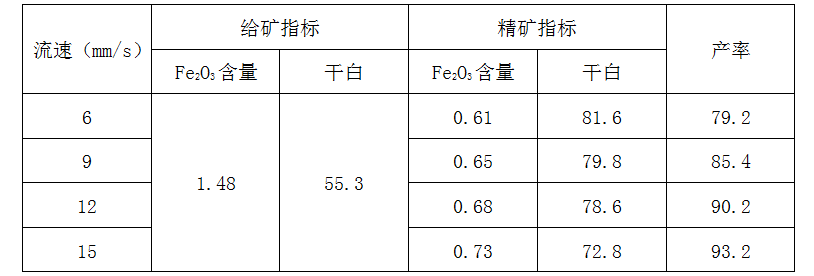

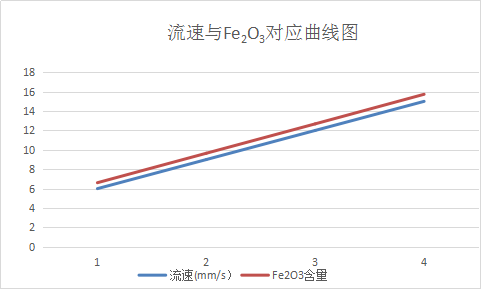

2.2.1 Izinga lokugeleza kwe-slurry: Uma izinga lokugeleza likhulu, isivuno se-concentrate siba phezulu, kanye ne-iron content nayo iphezulu; lapho izinga lokugeleza liphansi, i-concentrate iron content iphansi, futhi isivuno sayo sibuye siphansi. Idatha yokuhlola iboniswa kuThebula 2

Ithebula 2 Imiphumela yokuhlola yezinga lokugeleza kwe-slurry

Qaphela: Ukuhlolwa kwezinga lokugeleza kwe-slurry kwenziwa ngaphansi kwezimo zesizinda sikazibuthe esingu-1.25T kanye nomthamo we-disperant ongu-0.25%.

Umfanekiso 5 Ukuxhumana phakathi kwesilinganiso sokugeleza kanye ne-Fe2O3

Umfanekiso 6 Ukuxhumana phakathi kwesivinini sokugeleza nokumhlophe okomile.

Uma kubhekwa izindleko zokuhlomula ngokuphelele, izinga lokugeleza kodaka kufanele lilawulwe ku-12mm/s.

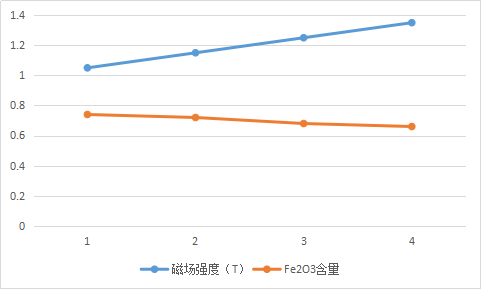

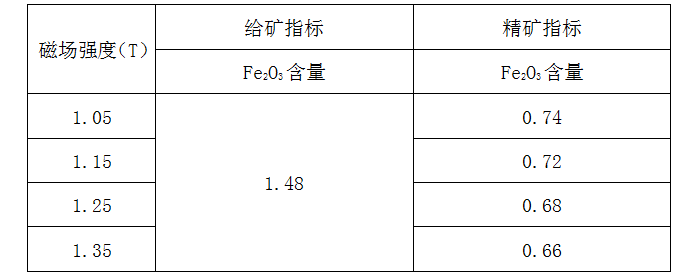

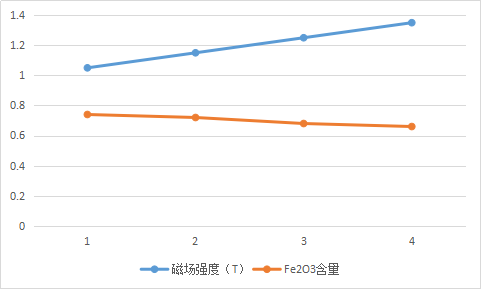

2.2.2 Isendlalelo indawo kazibuthe: Ingemuva lamandla kazibuthe wesihlukanisi sikazibuthe esiludaka liyahambisana nomthetho wenkomba yokukhipha insimbi yokuhlukanisa uzibuthe we-kaolin, okungukuthi, lapho amandla kazibuthe aphezulu, isivuno sokugxila kanye nokuqukethwe kwensimbi isihlukanisi kazibuthe zombili ziphansi, futhi izinga lokususa insimbi liphansi uma kuqhathaniswa. Umphumela ophezulu, omuhle wokukhipha insimbi.

Ithebula 3 Imiphumela yokuhlola yesizinda kazibuthe

Qaphela: Ukuhlolwa kwendawo kazibuthe yasemuva kwenziwa ngaphansi kwezimo zokugeleza kwe-slurry engu-12mm/s kanye nomthamo we-disperant ongu-0.25%.

Ngoba ukuphakama kokuqina kwesizinda sikazibuthe kuphezulu, amandla okuvusa aba makhulu, amandla asetshenziswa kakhulu okokusebenza, futhi ayanda izindleko zokukhiqiza iyunithi. Uma kucatshangelwa izindleko zokuhlomula, inkambu kazibuthe engemuva ekhethiwe isethwe ku-1.25T.

Umfanekiso 7 Ukuxhumana phakathi kwamandla kazibuthe nokuqukethwe kwe-Fe2O3.

2.3 Ukukhethwa kwenqubo eyisisekelo yokuhlukaniswa kazibuthe

Inhloso enkulu yokuzuza kwe-kaolin ore ukususa insimbi nokuhlanza. Ngokomehluko kazibuthe weminerali ngayinye, ukusetshenziswa kwendawo kazibuthe ene-gradient ephezulu ukususa insimbi nokuhlanza i-kaolin kuyaphumelela, futhi inqubo ilula futhi kulula ukuyisebenzisa embonini. Ngakho-ke, i-high-gradient slurry separator kazibuthe, i-coarse eyodwa nenhlawulo eyodwa, isetshenziswa njengenqubo yokuhlunga.

Ukukhiqizwa kwezimboni

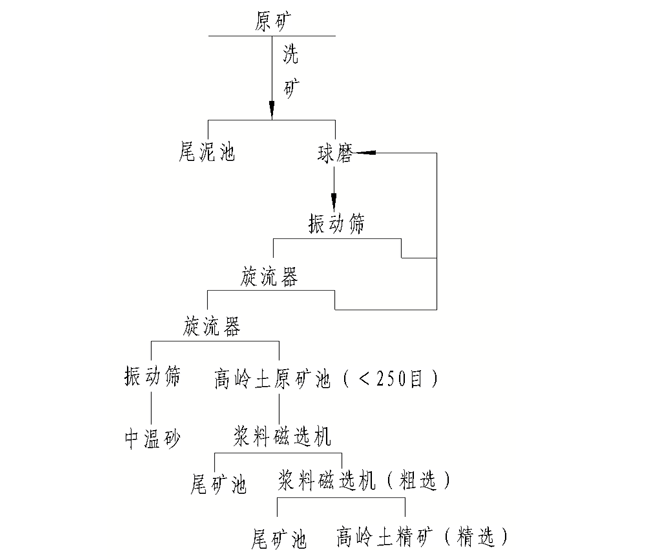

3.1 Inqubo yokukhiqiza yezimboni ye-Kaolin

Ukuze kukhishwe insimbi ku-kaolin ore endaweni ethile e-Guangdong, inhlanganisela yochungechunge lwe-HTDZ-1000 isetshenziselwa ukwakha inqubo yokuhlukanisa kazibuthe eqinile. Ishadi eligelezayo liboniswa kuMfanekiso 2.

3.2 Izimo zokukhiqiza ezimbonini

3.2.1Ukuhlukaniswa kwezinto ezibonakalayo: injongo eyinhloko: 1. Ukungcola okuhlukene okufana ne-quartz, i-feldspar ne-mica ku-kaolin kusengaphambili ngokusebenzisa isiphepho esinezigaba ezimbili, ukunciphisa ukucindezela kwezinto ezisetshenziswayo ezilandelayo, futhi kuhlukanise usayizi wezinhlayiyana ukuze kuhlangatshezwane nezidingo zemishini elandelayo. 2. Njengoba indlela yokuhlukanisa yesihlukanisi esinodaka kazibuthe ingu-3# uboya bensimbi, usayizi wezinhlayiyana kufanele ube ngaphansi kwezikhala ezingama-250 ukuze kuqinisekiswe ukuthi azikho izinhlayiya ezisele endaweni yensimbi yoboya ukuvimbela insimbi yoboya ekuvimbeni insimbi yoboya. , okuthinta inkomba ye-beneficiation kanye nokugeza okuphakathi Kanye nomthamo wokucubungula wemishini, njll.

3.2.2Izimo zokusebenza zokuhlukaniswa kazibuthe: ukugeleza kwenqubo kusebenzisa isivivinyo esisodwa esimahhadla futhi esisodwa esihle kanye nenqubo eyodwa yamaholoholo kanye neyodwa evulekile yesifunda. Ngokusho kokuhlolwa kwesampula, amandla enkundla yangemuva yesihlukanisi kazibuthe esine-gradient ephezulu ekusebenzeni okuqinile ngu-0.7T, isihlukanisi esinezinga eliphezulu kazibuthe sokusebenza kokukhetha yi-1.25T, kanye nesihlukanisi sikazibuthe se-HTDZ-1000 sodaka olubi sisetshenziswa. . Ifakwe i-HTDZ-1000 ekhethiwe yesihlukanisi esinodaka kazibuthe.

3.3 Imiphumela yokukhiqizwa kwezimboni

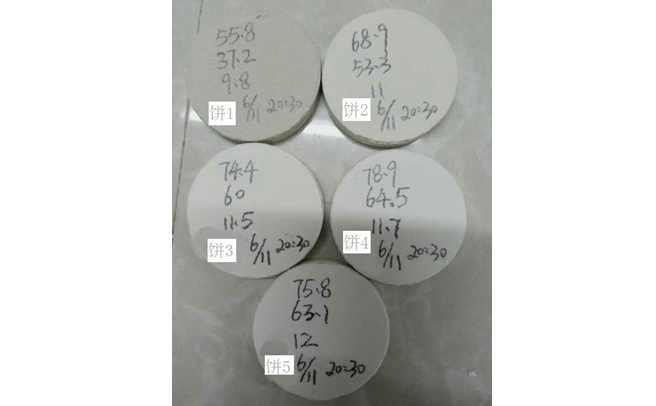

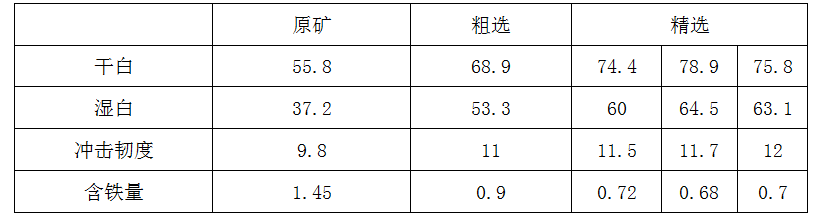

Ukukhiqizwa kwemboni ye-kaolin yokukhishwa kwensimbi endaweni ethile e-Guangdong, ikhekhe eliyisampula lomkhiqizo elikhiqizwe isihlukanisi esinozibuthe esinodaka oluphakeme lwe-HTDZ liboniswa kuMfanekiso 3, futhi idatha ikhonjiswe kuThebula lesi-2.

Ikhekhe 1: Isampula yekhekhe le-ore eluhlaza elingena kusihlukanisi esimahhadla samagnetic sokuhlukanisa

Uphaya 2: Uphaya oyisampula okhethwe cishe

I-Pie 3, Pie 4, Pie 5: Amasampula akhethiwe

Ithebula 2 Imiphumela yokukhiqizwa kwezimboni (imiphumela yokuthatha amasampula nokuhlephula amakhekhe ngo-20:30 ngomhla ka-6 Novemba)

Umfanekiso 3 Isampula lekhekhe elikhiqizwe i-kaolin endaweni ethile e-Guangdong

Imiphumela yokukhiqiza ibonisa ukuthi okuqukethwe kwe-Fe2O3 kokugxilisa ingqondo kungancishiswa cishe ngo-50% ngokusebenzisa ukuhlukaniswa okubili okuphakeme kozibuthe kodaka, futhi umphumela omuhle wokukhipha insimbi ungatholakala.

应用案例

Isikhathi sokuthumela: Mar-27-2021