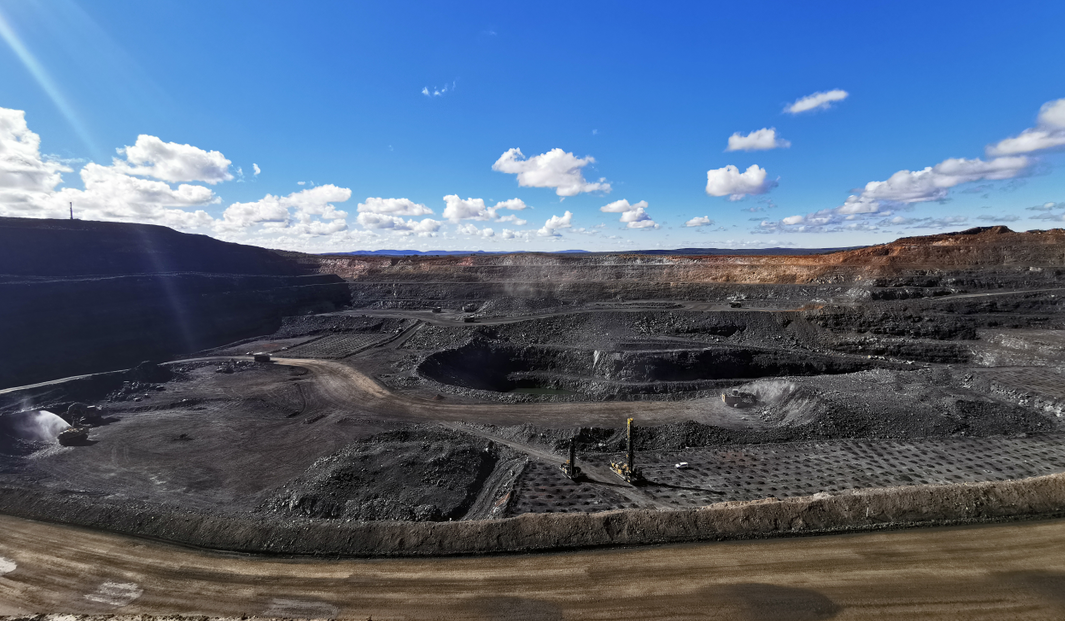

Ngenxa yokumbiwa okukhulu kwezimbiwa phansi zensimbi ezweni lami, izinsiza zayo ezilinganiselwe ziya ngokuya ziyindlala.Ngakho-ke, izidingo zemishini yokucubungula izimbiwa ziya ngokuya ngokuya phezulu, ikakhulukazi ukusetshenziswa okuphelele kwezinsalela kuhlobene ngqo nokuphikelela kwemithombo yezwe lami.Umbuzo uthi zisetshenziswa kanjani izinqubomgomo zokonga ugesi, zokunciphisa ukusetshenziswa, kanye nokunciphisa ukungcola okuhlongozwa uhulumeni, kugcinwe ukusetshenziswa kwesikhathi eside kwezinsiza, kanye nokwandisa inani lezinsiza sekuyindaba ebalulekile ebhekene nemboni yezimayini.

Njengamanje, isikhumulo sezindiza sokubuyisela umsila esisetshenziswe ekuhlukaniseni kazibuthe yensimbi eyinsimbi ezweni lami cishe i-1600Gs, futhi kunzima ukubuyisela amaminerali abuthakathaka kazibuthe kuma-tailings.Ngenxa yalesi sizathu, kunesidingo esiphuthumayo sokuthuthukisa okokusebenza okuzuzisayo okunamandla asezingeni eliphezulu futhi okukwazi ukwehlisa izinga lensimbi ensaleni ukuze kwandiswe ukusetshenziswa kwamanje kwezimbiwa ezweni lami.

I-Shandong Huate Magnetoelectric Technology Co., Ltd. iye yazibophezela ocwaningweni lwemishini yokubuyisela ukuhlukaniswa kwe-magnetite magnetic separation tailings kusukela ngo-2005. Njengamanje, inani elikhulu lama-ferrites akhiqizwa njengemishini yokubuyisela i-tailings magnetic, futhi uchungechunge oluthathu lwakhiwe.Imikhiqizo enezicaciso eziningi isiphenduke ithuluzi eliyinhloko lokuthola kabusha i-tailings.Ukuze kuqhutshekwe nokwenyusa izinga lokutholwa kwensimbi yemishini yokutakula insimbi, ngemva kophenyo olunzulu, ukuboniswa nokuhlolwa kokuhlaziya, ukusetshenziswa kwezinto ezinozibuthe ze-neodymium iron boron kanye nendlela yokuthulula endaweni engeyona enozibuthe kuye kwathuthukisa izinga lokutholwa kwensimbi. , futhi ukulayishwa kulula, okungahlangabezana nezidingo zokusetshenziswa.

Isakhiwo kanye nomgomo wokusebenza womshini wokutakula wamandla amaphakathi nenkundla we-semi-magnetic ukuzithulula izinsalela

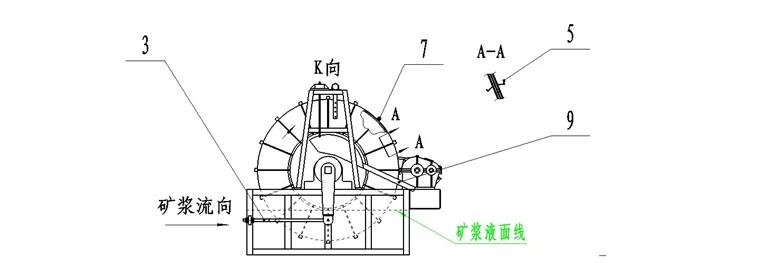

Umshini wokubuyisela umsila we-semi-magnetic dump oqinile omaphakathi nenkundla usebenzisa i-neodymium iron boron njengento kazibuthe.Isikhala sokuhlukanisa sinendawo enozibuthe emaphakathi nendawo enozibuthe ebuthakathaka.Izigxobo kazibuthe zishintshana zakha uhlelo lukazibuthe oluyindilinga eyindilinga.Ikesi ephendukayo inikezwa ngaphandle kwesistimu kazibuthe., Isistimu kazibuthe ilungisiwe, ingxenye yegobolondo icwiliswa ku-pulp, futhi izinhlayiya kazibuthe ku-pulp zimuncwa ngokuqhubekayo yindlela yokujikeleza okuqhubekayo.Izinhlayiya kazibuthe ziyaqhubeka nokuwa kanye nokuzungezisa i-casing, ukuze izinto ezingezona kazibuthe ezintweni zikazibuthe zihlale ziwashwa.Ingxenye engenhla kwesokudla yesistimu kazibuthe ye-semi-annular ayinayo indawo kazibuthe.Lapho izinto zikazibuthe zingena endaweni engeyona i-magnetic, ngaphansi kwesenzo samanzi okugeza kanye namandla adonsela phansi, Yehlisa impahla ku-concentrate tank.

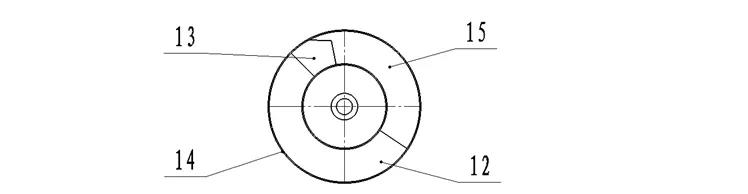

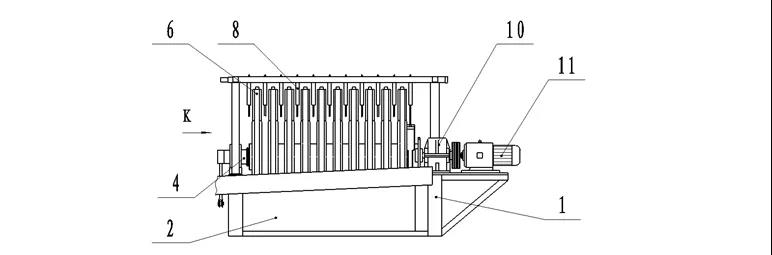

Umshini wokubuyisela umsila we-semi-magnetic self-unloading tailings uyisakhiwo esihlanganisiwe sohlobo lwe-disc, futhi inani lamadiski kazibuthe linganqunywa ngokuya ngezidingo zomthamo wokucubungula.Ukwakheka kwayo kuboniswe kuMfanekiso 1, 2, no-3. 1- ifreyimu;2 - ithangi le-slurry;3- indlela yokulungiswa kwediski;4- i-central shaft;5- isiphambukisi;Ithreyi yokuqoqa engu-6;7- block enyakazayo;8- ipayipi elishisayo;9- ukubamba i-chute;10 -Yehlisa;11-motor;I-12-indawo yamagnetic enamandla;I-13-indawo yamagnetic ebuthakathaka;14-fixed disk;Indawo eyi-15-non-magnetic.

Uhlaka lwenziwe ngensimbi eshiselwe futhi lusetshenziselwa ikakhulukazi ukusekela i-shaft ephakathi, ukufaka isistimu yokudlulisela kanye nokufaka ithangi le-slurry.

I-magnetic disc iyisakhiwo se-semi-magnetic, futhi i-disc yokuqoqa evaliwe ifakwe ngaphandle, i-magnetic conductive plate ihlanganiswe phakathi kwensimbi kazibuthe enezingqimba ezimbili, futhi ingxenye engezansi ye-disc yokuqoqa icwiliswa ku-slurry tank 2.

I-disc magnetic inikezwa insimu yamagnetic ephakathi, insimu yamagnetic ebuthakathaka kanye nendawo engeyona i-magnetic, futhi igxilwe ku-axis emaphakathi.

Iziphetho ezimbili zepani lokuqoqa zihlinzekwa ngobuningi bamapuleti angumhlahlandlela asakazwa ngendlela emise okwe-ray, futhi ubuningi bamabhulokhi ashukumisayo asakazwa ngokulinganayo anikezwa emaphethelweni angaphandle.

Njengamanje, amanye ama-concentrator ezweni lami asebenzisa imishini yokubuyisela i-disk tailings ye-medium-field-strength-strength, kodwa ngenxa yomphumela omubi we-desliming, i-magnetic material izodonsa emuva lapho okubalulekile kazibuthe kungena endaweni engeyona i-magnetic kusuka ku-medium magnetic field, futhi i-disk ne-scraper zigqoka ngokushesha., Kungaphansi kwemikhawulo ethile esetshenziswayo.

Ngenxa yalesi simo esingenhla, inkampani yethu yamukela i-mid-field-strength semi-annular disk enesakhiwo se-neodymium-iron-boron esivalwe ngokugcwele ukuze simiswe ku-axis emaphakathi, futhi i-axis emaphakathi igxilile ngaphandle kokujikeleza.I-pan yokuqoqa ephendukayo, ingxenye engezansi ye-pan yokuqoqa icwiliswa ku-slurry flow trough ukuze imunce izinto kazibuthe.Injini nesinciphisi kusetshenziswa ukushayela ithreyi lokuqoqa ukuze lizungezise, futhi okokusebenza kazibuthe okukhangiswayo kudlula endaweni kazibuthe emaphakathi nendawo enozibuthe ebuthakathaka, bese iphuma ngemva kokufinyelela inkambu engeyona enozibuthe, exazulula izinkinga ezingenhla.

I-chute yezinto ezibonakalayo ihlelwa phakathi kwepani ngalinye lokuqoqa, futhi izinto zikazibuthe epanini lokuqoqa ziyawashwa bese ziphumela ngaphandle eduze kwe-chute yezinto ezibonakalayo.

Isistimu yokudlulisela yenziwe ngenjini yokuguqula imvamisa, isinciphisi, i-coupling, umkhono wokudlulisela, njll. Izingxenye ezibalwe ngenhla zifakwe ku-shaft emaphakathi kanye nohlaka ukuze kubonakale ukuzungezisa okuqhubekayo kwethreyi lokuqoqa.

Ikhabhinethi yokulawula ifakwe ama-inverters, ama-switch switch kanye nezinye izingxenye zokulawula isivinini sokujikeleza kwe-disc magnetic nganoma yisiphi isikhathi.

Umazibuthe unomphela endaweni kazibuthe wakhiwa ucezu olulodwa noma izingcezu eziningi ekuqondeni kogqinsi, futhi iwebhu yediski egxilile ihlanganiswe phakathi.Indawo kazibuthe ithatha amasethi amaningi ezigxobo zikazibuthe ezinama-polarities aphikisanayo ukuze ahlelwe ngokushintshana.Ngesikhathi sokujikeleza okuqhubekayo kwe-pan yokuqoqa, izinto kazibuthe zihlala zidilika epanini lokuqoqa nasemanzini ukuze ziwashe futhi zichithe, ukuze izinto ezitholiwe kazibuthe zihlanganiswe nezinsika ezijwayelekile.Uma kuqhathaniswa nomshini wokugaya kabusha, ubumsulwa buphakeme futhi umphumela wokugaywa kabusha ungcono.

Indawo kazibuthe ebuthakathaka isethwe phakathi kwendawo kazibuthe kanye nendawo engeyona enozibuthe kudiski.Lapho izinto zikazibuthe zingena endaweni engeyona enozibuthe, ngenxa yendawo eguquguqukayo yensimu kazibuthe ebuthakathaka kanye nendawo yokumuncwa yamandla kazibuthe abuthaka kancane kancane iyancipha, ukwenzeka kokubuyela emuva kwezinto ezibonakalayo ziyancipha kakhulu.I-baffle ethambekele ethreyini yezinto ezibonakalayo iphinde ivimbele ukuhamba emuva kwezinto zikazibuthe kanye nokuvuza kwezinto, futhi ingenza izinto ezisebenza zibuthe zehle kancane kancane.Ngenxa yesenzo samandla adonsela phansi kanye namanzi okugeza, ukuthulula ngokushesha kuyabonakala.

Ithreyi lokuqoqa liyisakhiwo esingenalutho futhi esivalwe ngokugcwele, futhi indawo engaphezulu yezinto ezibonakalayo ezikhangisayo yakhiwe ngezinto ezingezona kazibuthe.Kuthreyi yokuqoqa, ipuleti likamhlahlandlela linezimbambo ngaphandle, ezithambekele e-engeli ethile nendawo yokugcina yethreyi yokuqoqa.Inhloso eyinhloko ukuvimbela uzibuthe.Ukunyakaza emuva kwezinto kanye nokuvuza kwezinto.Ukuze kuncishiswe idiphozithi ye-ore slurry, ubuningi bezigxobo ezinyakazayo zokushukumisa i-ore slurry zihlelwa eduze kwepani lokuqoqa, futhi ngesikhathi esifanayo, ukuhuzuka kwepuleti lokuqoqa ngenxa yokufaka idiphozi ye-ore slurry nakho kuyancishiswa. .

Isicelo sokukhiqiza izimboni

Ukuhlaziywa komthelela wokuthola kabusha womshini wokutakula we-semi-magnetic wamandla aphakathi nendawo ozikhululayo

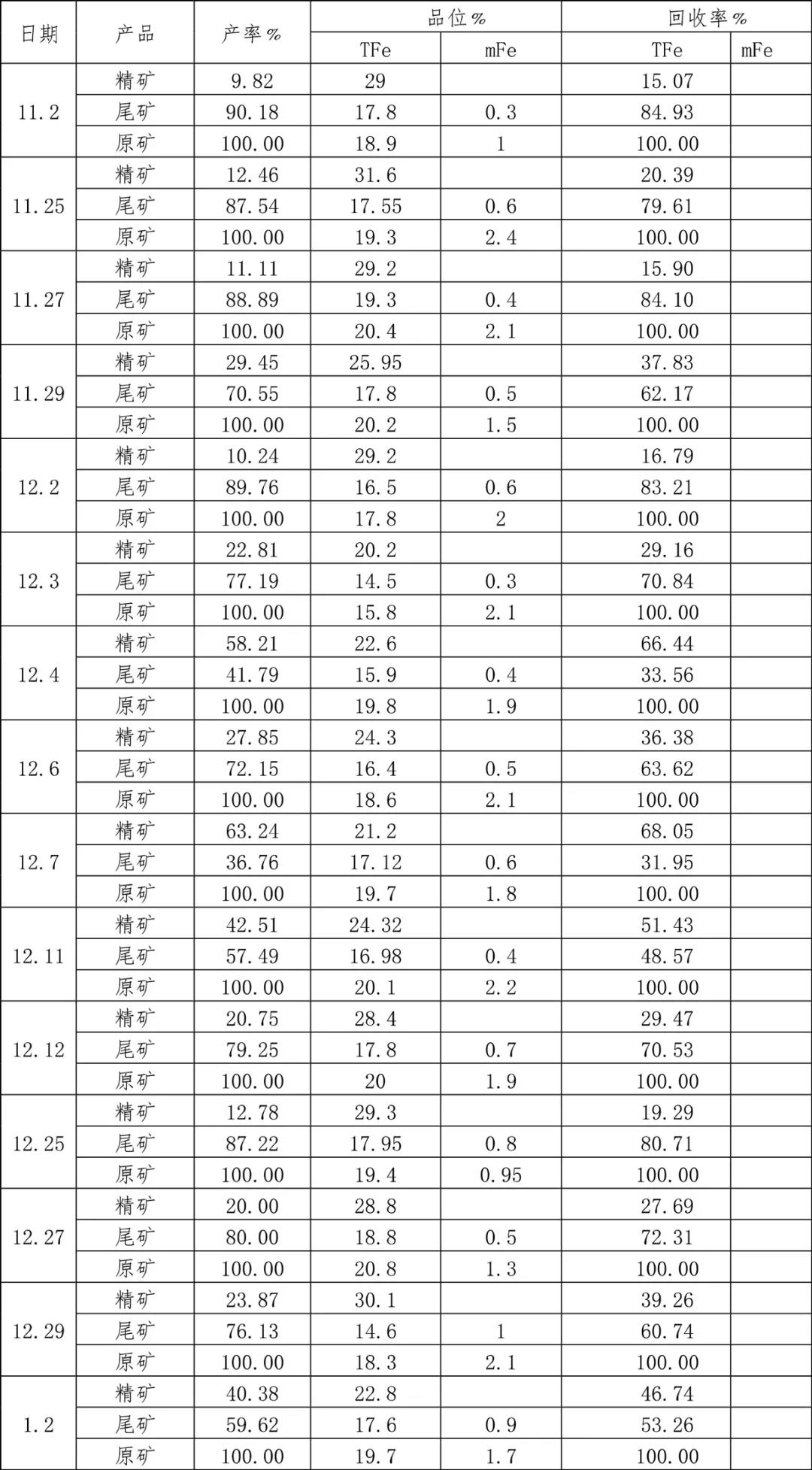

Umshini wokubuyisela umsila we-medium-field amandla ozibuthe ozikhululayo ozikhululayo onemodeli ye-YCBW-15-8 esetshenziswa inkampani yezimayini ufakwa ngemuva komshini wokutakula ama-tailings owakhiwe nge-ferrite ohlelweni lukazibuthe.Ngemva kwesikhathi esingaphezu kwesigamu sonyaka sokusebenza, Izinto zokusebenza zisebenza ngokujwayelekile futhi umphumela wokutakula muhle.Ngemva kokuhlolwa kwamasampula amaningi, imiphumela iyenelisa.Imiphumela yokuhlolwa kwamasampula amaningi imi kanje:

Ngokuhlaziywa kwedatha okungenhla:

Umthelela wokuthola kabusha le mishini: ibanga lemisila lincishiswe ngo-2.16% ngemva kokuhlunga, izinga lensimbi kazibuthe lincishiswa ngo-1.27% ngemva kokuhlunga, futhi izinga elijwayelekile lensimbi ephakathi lingama-26.53%.Umphumela wokubuyisela uyabonakala.

Amathemba emakethe kanye nezinzuzo zezomnotho

Njengamanje, kunamabhizinisi amaningi okuhlukanisa kazibuthe e-China, futhi ambalwa kuphela awo asebenzisa imishini yokutakula i-ferrite tailings, kodwa angasebenzisi imishini yokutakula i-tailings yamandla aphakathi nendawo ye-semi-magnetic self-unloading tailings.Ngakho-ke, ithemba lemakethe libanzi.Uma u-20% wamagnetic Isitshalo sokucubungula sitshala kule mishini, ibalwa ngokusekelwe kumayunithi angu-300 ngonyaka kanye nemodeli ye-YCBW-15-8.Iyunithi ngayinye ingabuyisa u-7t/h wensimbi eyomile ngehora, i-ore eyomile eyi-168t/h ngosuku, kanye nezinsuku zokusebenza ezingama-330 ngonyaka, ukutholwa sekuphelele amathani ayizigidi ezingama-55.44, kanye nesamba esingamathani ayizigidi eziyi-16.632 aphinde asetshenziswa ngamayunithi angama-300.Izinzuzo zomnotho zinkulu, futhi ukusetshenziswa kwalesi sixhobo kunganciphisa ukumoshwa kwenani elikhulu lezimbiwa ezweni minyaka yonke.

Njengamanje, izinga le-tailings yensimbi eyinsimbi ezweni lami ngokuvamile liphezulu ngemva kokuhlunga, okubangela ukumoshwa kwezinsiza eziningi.Imithombo yamaminerali iyisisekelo sokuphila nokuthuthuka komuntu.Amandla angaphezu kwama-95% kanye nama-80% ezinto zokusetshenziswa zezimboni ezweni lami atholakala ezimayini.Ngokuthuthuka ngesivinini komnotho wezwe lami, isidingo sezimbiwa phansi silokhu sikhula.Ngakolunye uhlangothi, imithombo yezokumbiwa phansi yezwe lami ibhekene nengcindezi enkulu yokuntula okwandayo.Izimbiwa ezisezingeni eliphezulu, okulula ukuzihlunga ziyehla, kanti nezimbiwa phansi ezisezingeni eliphansi, okunzima ukuzihlukanisa ziya ngokuya ziba yigugu.Ukwakhiwa nocwaningo lwemishini yokubuyisela umsila ngaphezu kwama-300mT kunomthelela omuhle ekwehliseni ukumosheka kwemithombo yezwe kanye nokwandisa izinga lokusebenzisa imithombo yezimbiwa.Ngokombono wentuthuko kanye nemiphumela yohlelo lokusebenza, ithuthukise ngempumelelo izinga lokutholwa kwe-ore kazibuthe.Ihlangabezana nezidingo zokuklama futhi iwumkhiqizo ofanele ukukhuthazwa nokusetshenziswa.

Isikhathi sokuthumela: May-12-2021