I-WHIMS Indandatho Emile Emile Isihlukanisi Sezibuthe Esiphezulu

Isicelo

Ukuthuthukiswa

Izinzuzo ze-LHGC Ngaphezu Kwendandatho Eqondile Yendabuko ye-WHIMS

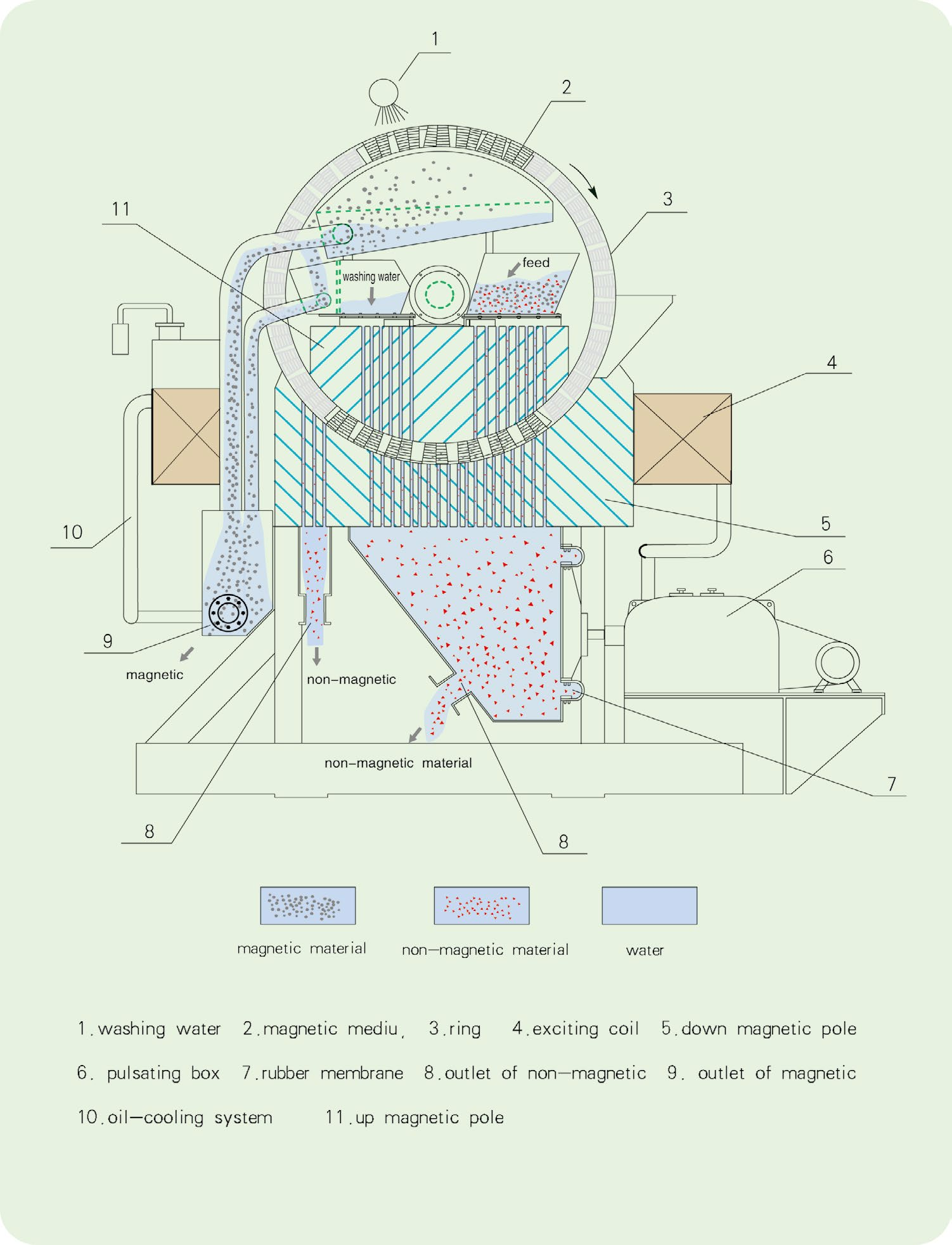

I-LHGC uwoyela-amanzi okupholisa indandatho eqondile yesihlukanisi kazibuthe (WHIMS) isebenzisa inhlanganisela yamandla kazibuthe, uketshezi oludonsayo kanye namandla adonsela phansi ukuze ihlukanise ngokuqhubekayo amaminerali kazibuthe nangewona kazibuthe. Inezinzuzo zomthamo omkhulu wokucubungula, ukuhlomula okuphezulu

ukusebenza kahle kanye nezinga lokutakula, ukuncishiswa okuncane kokushisa kwenkundla kazibuthe, ukukhishwa okuphelele, nezinga eliphezulu lobuhlakani.

I-LHGC vertical ring high gradient separator kazibuthe (WHIMS) inokwethenjelwa futhi kulula ukuyisebenzisa nokuyinakekela, futhi I-inthanethi Yezinto Nobuchwepheshe Be-Cloud Platform isetshenzisiwe ukuze kuqaliswe ukusebenza okuzenzakalelayo okuhlakaniphile. Ukuze uqhathanise ne-WHIMS evamile, i-LHGC yamukela inani lobuchwepheshe nezinqubo ezintsha, ezithuthukisa ngempumelelo ukusebenza kahle, ukunemba kokuhlukana nezinga lokulahla umsila, kanye nezindleko eziphansi zokunakekela nezokusebenza.

Izici Zobuchwepheshe

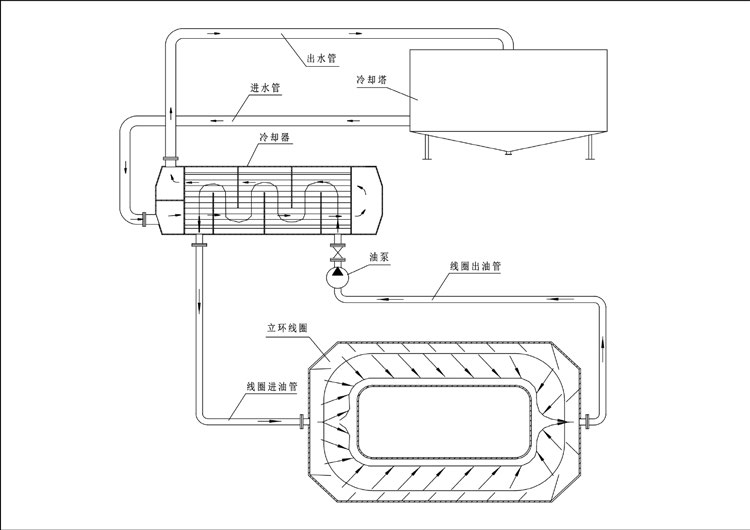

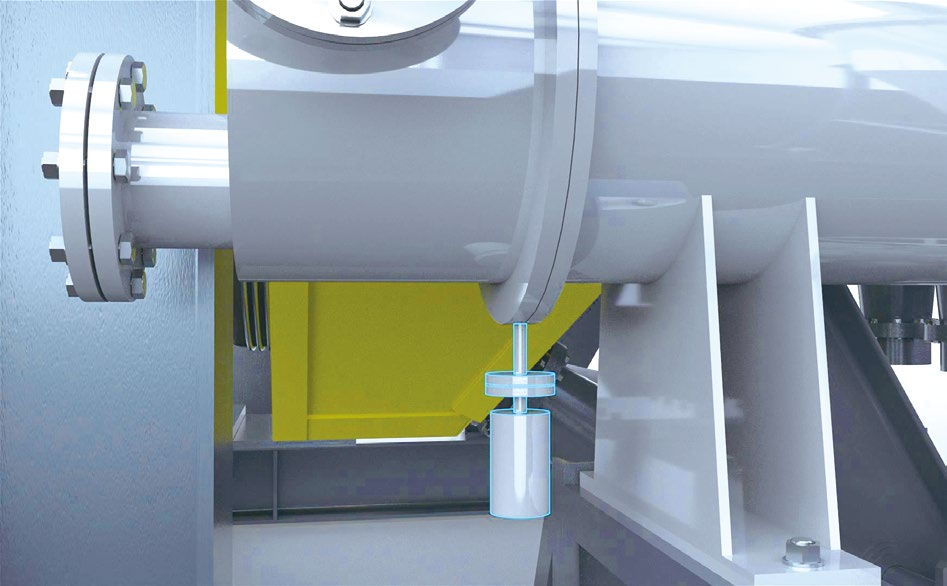

I-Oil-water Heat Exchange Cooling Technology

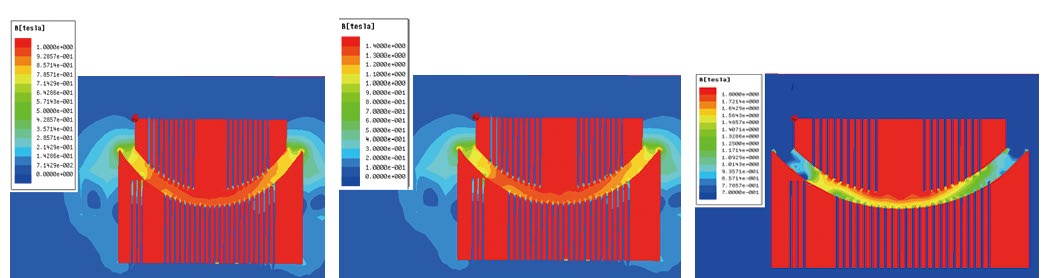

Idizayini Yesekhethi Yezibuthe Ezinembile

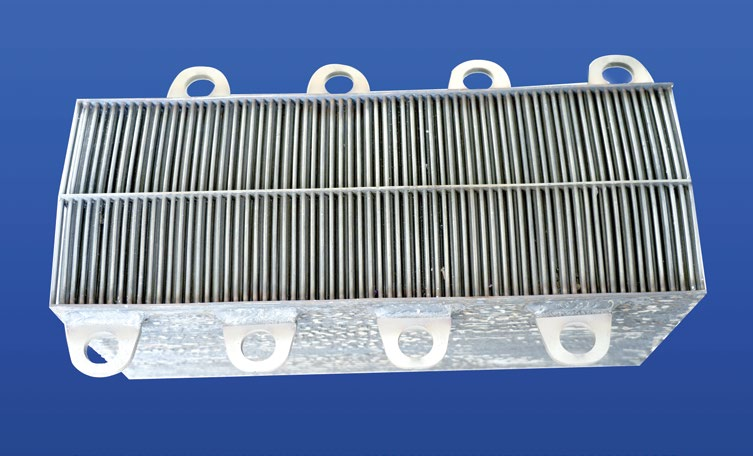

Impilo ende Edidiyelwe I-Matrix Magnetic

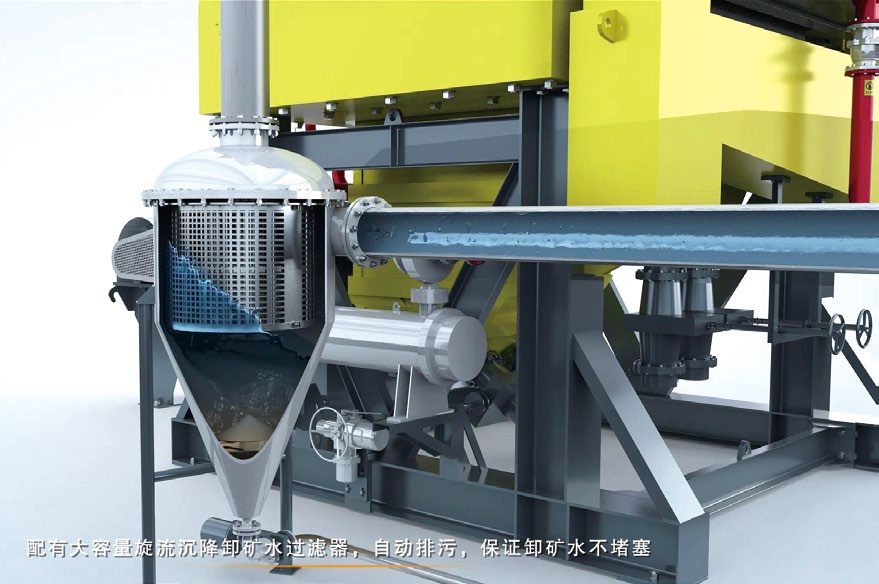

I-Automatic Cyclone Sedimentation Filtration System

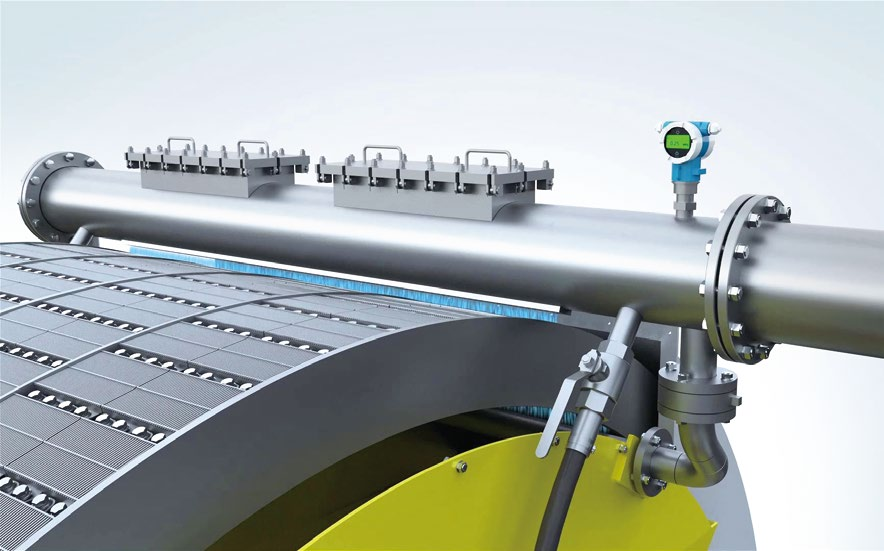

Uhlelo Lokukhipha Amaminerali Amanzi Amanzi

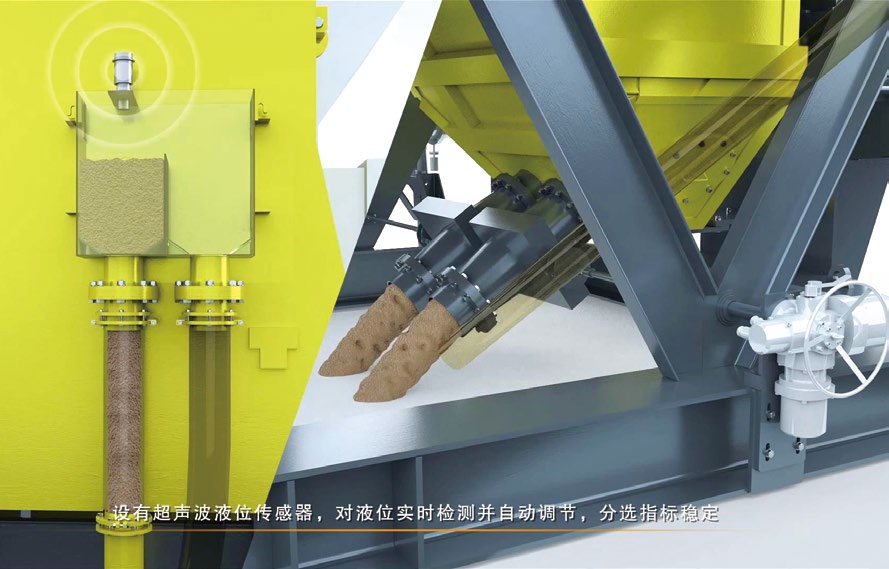

I-Liquid Level Automatic Control System

Isimo sokuguquguquka kwezinga le-liquid ekamelweni lokuhlukanisa sitholwa ngesikhathi sangempela yinzwa ye-ultrasonic, futhi ixhunywe ne-actuator kagesi, ukuze izinga le-liquid lekamelo lokuhlukanisa lihlale lisesimweni esihle kakhulu sokuhlukanisa; ukusebenza okwenziwa ngesandla kuyancishiswa, futhi ubunzima bokuhlola okwenziwa ngesandla buyehliswa; umthamo oweqile we-slurry esheshayo uyavinjelwa ukugwema ukuchichima.

I-Temperature Alarm Protection System

Izinzwa zokushisa kwamakhoyili zinikezwa ukuze zibone ukushisa okusebenzayo kwekhoyili ngesikhathi sangempela futhi zibuyisele ukwaziswa endaweni yokulawula. Lapho izinga lokushisa yikhoyili lidlula inani elibekiwe, isistimu izokhala ngokuzenzakalelayo, futhi okokusebenza kuzoyeka ukusebenza lapho umkhawulo ongaphezulu ufinyelelwe ukuze kuqinisekiswe ukusebenza ngokuphephile kwezinto zokusebenza.

Idivayisi ye-alamu yokuvuza

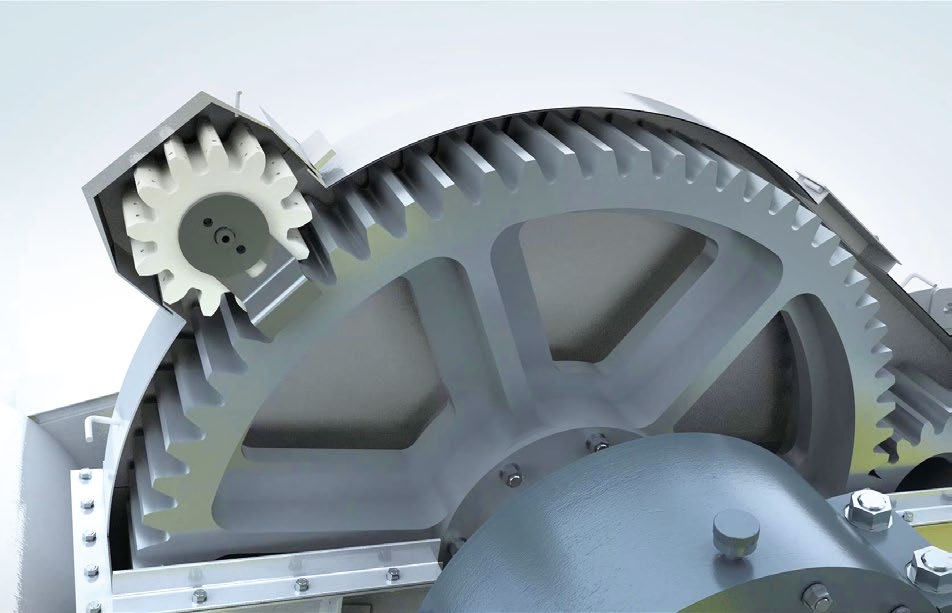

Automatic Lubrication System

Igiya le-ring drive lithatha ithuluzi lokuthambisa elizenzakalelayo legiya elingasebenzi ukuze liqinisekise ukuthi okokusebenza kungathola ukuthambisa okuzenzakalelayo ngaphandle kokumisa ukusebenza futhi kuthuthukise izinga lokusebenza.

I-Remote Intelligent Service Platform Isekelwe Ku-inthanethi Yezinto Ubuchwepheshe

Isimiso sokusebenza

Isimiso sokusebenza

I-slurry yethulwa ku-hopper yokuphakelayo ngepayipi lokuphakelayo, bese ingena kumagnetic matrix eringini ezungezisayo eduze kwezimbobo zesigxobo sikazibuthe esiphezulu. I-matrix kazibuthe idonsa uzibuthe, futhi insimu yamagnetic ephakeme kakhulu yenziwa endaweni yayo. Izinhlayiya kazibuthe

zikhangwa phezu kwe-matrix kazibuthe, futhi zilethwa endaweni engeyona enozibuthe phezulu ngokuzungezisa kwendandatho, bese zidluliselwa ku-hopper yeqoqo ngokushaywa kwamanzi ngomfutho. Izinhlayiya ezingezona kazibuthe zigelezela ku-hopper yeqoqo lezinto ezingezona uzibuthe eduze kwezikhala esigxotsheni sikazibuthe esiphansi ukuze zikhishwe.

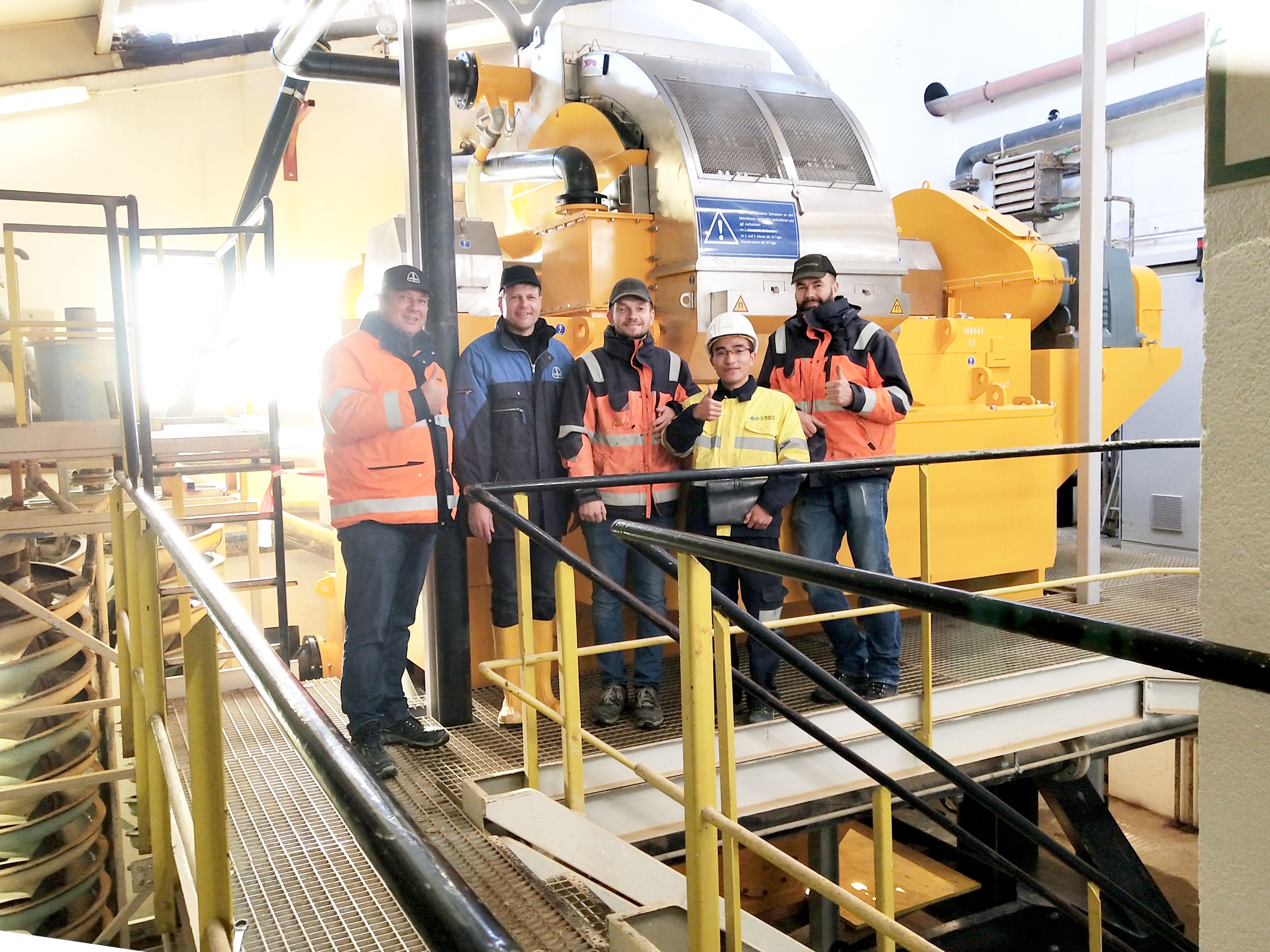

I-Case Scene